Tetradecanedioic acid didn’t show up out of nowhere in the world of chemistry. Its story stretches back to the middle of the 20th century, during an era when scientists pushed for better synthetic materials. I noticed that early pioneers in polymers sought diacids with longer carbon chains, not content with shorter molecules. They found longer-chain analogs of common dicarboxylic acids suitable for new synthetic fibers. In the years that followed, markets shifted. Interest grew in high-performance plastics — the kind used for engineering and automotive components. Somewhere along the way, Tetradecanedioic acid carved out a niche, aided by advances in petrochemical processing and later by the promise of greener, bio-based production. Through every turn, industry hungered for molecules that could bring better thermal stability, chemical resistance, and flexibility to final goods.

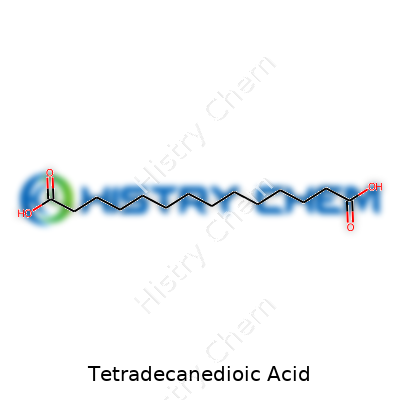

People working in chemical plants or material labs often come across Tetradecanedioic acid. It shows up as a solid, with a waxy texture, forming colorless or white crystals. Chemists rely on its structure—fourteen carbons with a carboxyl group stuck to each end—to unlock specific features in custom polymers. They value it for backbone length and predictable behavior, traits that shorter and longer diacids can’t always match. Markets that focus on polyamides, specialty polyesters, or corrosion-resistant coatings keep asking for this acid due to its consistency and reliability in performance recipes.

Tetradecanedioic acid warms and softens at a specific melting point, around 127 to 131°C. It dissolves slowly in water, but blends easily with hot alcohols or acetone. The acid’s long hydrophobic chain gives finished products a balance of flexibility and rigidity, a reason why engineers and designers pick it for demanding environments. Its two carboxyl groups react with diamines, alcohols, and other partners, ensuring tight connections in final polymers. After working with the raw powder, I noticed the odor is faint, mostly present after heating, and handling doesn’t stir up much dust, something appreciated in labs and factories that aim to keep air clean and safe.

Manufacturers sell Tetradecanedioic acid with detailed paperwork, listing purity, melting point, moisture content, and residue limits. I’ve seen common purities climb above 98%, supported by gas chromatography and titration tests. Packages come sealed in polyethylene or paper-lined bags, labeled with the product’s name, molecular formula, weight, batch number, and hazard warnings. These specs aren’t there just for regulatory agencies; chemists check every batch for these numbers to ensure downstream reactions go as planned and to avoid surprises in finished goods.

The most straightforward route starts with 1,14-tetradecanediol, often sourced from petrochemicals but now produced using biological fermentation. In conventional settings, oxidation—using catalysts and controlled heat—transforms the diol into the desired diacid. New methods use engineered microbes fed on plant oils, promising better yield and less pollution. These newer processes cut down on heavy metals and toxic byproducts, a goal set by both environmental groups and companies aiming for long-term sustainability.

Chemists value Tetradecanedioic acid for its ability to form amides, esters, and other building blocks. Combined with diamines under heat, it yields polyamides that stand up to tough wear and tear. Blending with alkanolamines creates plasticizers and specialty lubricants. The two acid groups anchor to metal ions or link block copolymers, opening doors to advanced materials used in demanding industries. Some R&D labs experiment with hydrogenation, seeking to tweak the backbone for custom flexibility or linking it with other biobased units to produce even more specialized polymers.

The clear IUPAC term—tetradecanedioic acid—sticks with chemists, but catalogs list it under alternative names like 1,12-dodecanedicarboxylic acid, or abbreviated as TDDA. Vendors include trade names that reflect branded processes or purity grades, though the root molecule stays the same. For supply teams, double-checking these aliases on shipping documents prevents costly mix-ups, especially when similar-sounding diacids are stacked nearby in a warehouse.

Most guides and safety data sheets list Tetradecanedioic acid as a low-risk chemical for daily use. Gloves and goggles, along with decent ventilation, easily handle the main hazards. Swallowing or contact with eyes stings but does not cause significant injury under typical exposure. Storage in a dry, cool place prevents clumping or degradation. For sites with dust control rules, using extraction fans and sealed bins keeps airborne particles out of workspaces. Chemical teams carry out regular checks on storage conditions, and staff training often covers safe handling, spill response, and first aid, keeping incidents rare.

Polymer manufacturers stand out among the largest users of Tetradecanedioic acid. They shape it into polyamides for engine parts, gears, electrical connectors, and fuel lines—foreshadowing modern automotive and electronics industries driven by stricter standards. Medical device makers use biocompatible grades for surgical stitches and suture coatings, leveraging the acid’s chain length for the right blend of strength and slow breakdown in tissue. Some companies experiment with coatings that block corrosion in oil pipelines, while others target consumer goods like performance fibers and new textile finishes. The reach extends each year as more sectors uncover uses for high-purity, long-chain dicarboxylic acids.

Research in university and industrial labs keeps trying to stretch the boundaries of Tetradecanedioic acid. I’ve followed several projects where scientists work with catalysts to speed up reactions or improve selectivity, producing less waste and reducing costs. Others focus on fermentation, turning sugar beets or even algae into feedstock, hoping for greener chemistry. There’s another group tackling compatibility—mixing Tetradecanedioic acid into existing polymers to see if they can make parts lighter or more durable. The drive for innovation shows that no molecule, no matter how established, sits idle in the face of better performance and tighter environmental rules.

Toxicology studies aim to answer the same questions for every new or old industrial chemical: is it safe, and at what exposure? Standard oral and skin tests find that Tetradecanedioic acid doesn’t cause acute harm. Animal testing for chronic effects shows little cause for concern at ordinary exposure. Still, researchers post updates, pressing for transparency and keeping up a safety record. Alongside these formal studies, medical teams study occupational health, logging any pattern of allergy or irritation among workers who handle significant amounts for long periods. So far, the substance remains low in hazard, but ongoing scrutiny keeps risks from catching anyone off guard.

Interest grows as industries look for better ways to make materials with less environmental baggage. Biotech companies invest in bio-based routes, using microbes to make Tetradecanedioic acid from renewable sources. New patents trickle in for polymers built on TDDA backbones, targeting products that need both toughness and chemical resistance. Policy shifts, especially in Europe and North America, push for materials that break down cleaner or use less fossil fuel in manufacturing. I expect to see Tetradecanedioic acid spread into new fields—from high-end electronics enclosures that need to last decades, to disposable consumer items needing quick, safe turnover—relying on ongoing research, tight quality standards, and sustainable methods.

Tetradecanedioic acid rarely grabs headlines on its own. Still, this long-chain dicarboxylic acid plays an unseen but crucial role in many things we all rely on. In the world of manufacturing, Tetradecanedioic acid gives backbone to high-performance nylon and polyesters. The presence of this acid in certain polymer formulations lets engineers produce fibers and plastics that shrug off heat, moisture, and wear. Think about the rugged carpet at commercial spaces, the seat fabric in newer cars, or even the smooth, flexible plastic parts in household electronics—there’s a good chance this acid helped get them there.

The polymers built from Tetradecanedioic acid often end up in products you count on to last. In the automotive field, for example, these materials help engineers create engine parts and electrical connectors that don’t warp or degrade under the hood. Those same plastics shape water-resistant electronics and mobile device housings, providing protection in the rain and in humid climates. Technically, its long carbon chain offers just the right balance between rigidity and flexibility, making components far less likely to crack under stress.

Factories turn to Tetradecanedioic acid for another reason: it fits with current moves toward sustainable production. Some leading manufacturers now produce this acid through fermentation, using yeast and plant oils instead of crude oil. The bio-based approach slashes the carbon footprint and reduces toxic waste. I’ve watched companies who take this route receive real credit from buyers for cleaner sourcing. Research from the American Chemical Society journals backs up environmental claims, showing significant emissions savings with bio-route production.

Medical researchers also keep Tetradecanedioic acid in their toolkit. This acid helps them build drug delivery systems and biodegradable medical implants. These medical polymers gently break down in the body—important when doctors want to deliver medicine directly to one area, or leave a support in place that eventually dissolves. My experience with folks in medical device startups tells me that materials from this acid allow them to build new types of absorbable stitches and bone scaffolds that perform reliably when health is on the line.

Still, Tetradecanedioic acid isn’t perfect. Lab and field tests can reveal purity issues or variability when switching from petroleum-based to plant-based sources. Companies trying to scale up fermentation can run into cost overruns if processing steps aren’t tuned right. Global supply chains also get tangled when patents and trade policies block the use of newer, greener fermentation-tech.

The biggest step forward would come from investment in open research and simpler, cheaper fermentation processes. Collaboration between suppliers, chemists, and end-product manufacturers will support better transparency about material sourcing and performance. Crowdsourcing knowledge—open data on test results, standardized checks for purity—could give both buyers and environmental groups confidence in wide-scale adoption.

Materials like Tetradecanedioic acid connect to so many modern comforts and advances. If the people making and using it stay focused on quality, safety, and sustainability, it’s possible to have both better products and a smaller environmental bill in the end.

Tetradecanedioic acid carries the formula C14H26O4. That means it holds fourteen carbon atoms, twenty-six hydrogens, and four oxygens. Two carboxylic acid groups mark the ends of its straight, fourteen-carbon chain. This molecule stands out because it’s not something you find at the grocery store—it links up in special ways to create things most folks wouldn’t even know have a chemical name behind them.

Polymers use chemical building blocks much like carpenters choose lumber. Many specialty nylons start with a dicarboxylic acid, and tetradecanedioic acid has just what's needed for high-performance plastics. It brings durability and flexibility, which show up in car parts, coatings, and even medical devices. That’s not just fancy science—real, practical products come from getting this structure right at the molecular level.

The long, even spacing in the acid’s backbone allows for predictable melting points and ruggedness. Take it from someone who has fixed a cracked bumper: modern car panels owe a ton to these advanced materials. Tetradecanedioic acid helps avoid brittleness, keeping plastics useful in hot summers or freezing winters without breaking apart.

Factories have pushed for greener methods over the past decade. Makers once relied mainly on petroleum. Researchers and companies have started using fermentation, letting microorganisms build that lengthy carbon chain from renewable sugars. By reducing fossil input, the industry creates less carbon dioxide and cuts dependence on oil. Companies like Cathay Industrial Biotech have scaled these biotechnologies, showing that big-volume production can switch to plant-based feedstocks.

Supply chains still raise issues in chemical production. Working with carboxylic acids calls for good ventilation and handling, as skin or eye contact leads to irritation. Regulators look for companies’ compliance with workplace safety rules and environmental controls, so that runoff and byproducts don’t pollute water or soil. More transparency builds public trust; chemical makers should post safety data and environmental audit results openly.

Facing climate targets, chemical producers have to pick up the pace on sustainable sourcing and energy use. More research can squeeze efficiency from fermentation, using engineered microbes or lower-impact solvents. I’ve watched new startups experiment with upcycling plastic waste, breaking it down to dicarboxylic acids, which could feed right into this supply chain. That approach could solve part of the plastic waste dilemma without waiting for new raw materials.

More people should see the direct link between molecular structures and the goods in closets, garages, and doctor’s offices. Understanding the chemistry behind tetradecanedioic acid connects people to the everyday materials they count on—and can help drive smarter, safer choices for the environment and our own health.

Tetradecanedioic acid crops up in industries like plastics, lubricants, coatings, and even some specialty adhesives. Manufacturers use it to make polymers tougher, more flexible, or resistant to aggressive chemicals. My first encounter with this chemical came in a research lab, where staff measured out white powder with care, always wearing masks and gloves. At first glance, the risks looked minor, but a little digging changed my view.

Sifting through scientific studies, most label tetradecanedioic acid as a low-hazard material. It doesn’t ignite easily and doesn’t rank high on the scale of acute toxicity. Not long ago, the European Chemicals Agency published data showing that workers exposed to its dust in poorly ventilated spaces sometimes complained of throat irritation and itchy skin. Milder symptoms clear up by stepping outside or rinsing off, but direct contact over long periods may lead to rashes or even asthma-like symptoms for those sensitive to powders.

In factories, risk grows with lack of protective gear. Research shows most commercial users wearing proper gloves and fitted respirators rarely report trouble. Skin absorption rates look low, and there’s no major evidence of long-term buildup in human tissue. That said, families rarely stumble across pure tetradecanedioic acid in household products. Finished goods—like molded plastics or treated textiles—don’t shed this acid in their final form, so household exposure stays tiny unless someone in the home works at a production facility. A friend of mine who managed a plant in central Texas shared that occasional spills made a mess but rarely needed more than prompt cleanup and better ventilation.

Studies from the National Library of Medicine show that tetradecanedioic acid breaks down in the environment over weeks to months. Wildlife risks appear limited, and bioaccumulation looks unlikely based on tests in fish and soil. Still, leaks in large quantities could stress local water systems. To avoid runoff problems, environmental scientists recommend safe storage, spill plans, and basic monitoring. Factories following these guidelines rarely run into trouble with environmental regulators.

On job sites, a few habits cut the risk. Always work in well-ventilated spots or use extraction hoods. Disposable nitrile gloves work better than bare hands. Respirators with basic particulate filters cover most scenarios where dust may rise. Changing out of work clothes helps too; carrying fine powder home on clothing can irritate young children or the elderly. Washing hands—before meals and at the end of the shift—protects against accidental ingestion. These measures come from people who have spent years handling all sorts of industrial acids, including this one.

Producers and regulatory agencies aim for clarity in guidelines, labeling, and emergency support. Easy-to-read safety sheets, ongoing workplace audits, and public access to chemical records increase trust and lower accident rates. Some workplace leaders hold “toolbox talks” at the start of each shift, walking through common-sense precautions. As safer manufacturing spreads, accidental exposures become rare, and workers feel more confident in their routines.

Handling tetradecanedioic acid at work taught me pretty quickly that chemicals with tough-sounding names come with surprisingly practical storage needs. At first glance, this white powder looks as innocent as baking soda, but anyone with a background in chemistry knows it can hold to its own in moisture-rich rooms. Leave the container open in a humid lab, and you'll find yourself scraping blocky clumps that take twice as long to dissolve.

The most obvious enemy is water. Moisture doesn’t just cake up the powder; it can kick off slow breakdown or contamination. Even a screw lid can let damp air creep in. I’ve seen whole batches rendered useless just because folks got careless—an expensive lesson for any team. Store it in a tightly sealed container—a glass jar or high-density polyethylene bottle do the trick. Add a desiccant packet if you’ll open the bottle regularly, just like they always recommend in pharma labs.

Sunlight deserves mention too. UV light warps some chemicals or jumpstarts weird reactions, and acid compounds sometimes act up under hot beams. Better to keep the jar tucked away in a dark cabinet, even if storage instructions don’t scream “light-sensitive.” A cool, dry place means away from radiators, autoclaves, and lab windows. If you’re used to shelving sodium chloride in a kitchen cupboard, shift habits for this one: fluctuations in temperature and humidity land you in trouble faster than for table salt.

Stable chemicals often lull users into bad habits. Tetradecanedioic acid holds well at room temperature, as long as it gets a little respect. I’ve pulled sample jars after five or six years of careful storage and found them as powdery as day one. Still, any new order comes with a manufacturer’s batch label and expiry—ignore those and you’re asking for unpredictable results in downstream experiments. Never trust an unlabeled sample; it costs nothing to write down the arrival date or stick on a barcoded batch number. More than once, precise record-keeping saved our lab from mixing up look-alike acids and blowing a routine synthesis.

In shared environments, a chemical can disappear or wind up in the wrong hands. Label every bottle in plain language. If you swap the content to a smaller jar, mark the change immediately. Someone once helped themselves to my “unlabeled white powder” and it turned into a guessing game when their project failed. Communication and clear storage go hand in hand. For hazardous spills, this acid rates pretty low, but breathing in fine dust or getting powder in your eyes is no picnic. Gloves, lab coats, and a dust mask cut down on slip-ups—real steps, not wishful thinking.

Institutions love automated inventory tracking, and I can’t recommend it enough. Scanners or spreadsheets keep storage headaches away, especially for chemicals that look dangerously similar. Few places dispose of expired stock promptly, and I’ve fished out crusty jars that should have left ages ago. Setting a monthly reminder for stock checks and cleaning makes sure your storage area stays safe.

After working with hundreds of chemicals, this one stands out for being solid, simple, but easy to abuse if you slack on basics. A dry jar, a clear label, and a dark shelf take you far. Skip those, and you’re risking wasted money—and wasted lessons.

Tetradecanedioic acid pops up as a specialty chemical in applications that include resins, polyamides, lubricants, and research formulations. Tracking it down for legitimate use isn’t impossible, but you quickly run into hurdles if you only know your way around regular retail or pharmaceutical suppliers.

Anyone searching for it often gets frustrated with information scattered across forums or sketchy online outlets. The real question never feels fully answered: Where do honest folks source this compound without stumbling into legal or quality traps?

My days in the lab taught me to chase down reagents with reputable paperwork. Tetradecanedioic acid, like most specialty chemicals, brings risks if purity is off. Impurities in this molecule can mess up final polymer properties, cause batch-to-batch variability, or even raise safety red flags during handling. Companies and universities know this risk. That’s why procurement officers hammer on certificates of analysis and documented supply chains.

Companies like Sigma-Aldrich (now under MilliporeSigma in the US), Alfa Aesar, TCI America, and Santa Cruz Biotechnology all list tetradecanedioic acid in their catalogs. They ask for details on intended use, shipping address, and credentials proving you aren’t buying it for malintent. Reliable suppliers require institutional affiliation or proper licensing from verified research facilities. Places that don’t enforce these checks rarely offer genuine quality.

Lab suppliers do list tetradecanedioic acid, but they keep pricing and shipping quotes guarded for a reason. Chemical regulations vary by country and state, and banned end uses keep both buyer and seller in a maze of restrictions. Even for small research batches, prices fluctuate based on purity, pack size, and transportation restraints.

Some users get tempted by e-commerce sites or overseas “direct-from-factory” sales at dirt-cheap prices. Truth is, those sources come with big risk. The lot could be poorly stored and already degrading. Mislabeling sometimes lands buyers in unwelcome legal trouble at customs. I’ve seen labs return whole shipments because contaminants ruined meticulous projects. Retracing your steps through grey-market supply chains gets expensive and introduces questions about lab safety.

Universities and research groups have procurement teams for a reason—they handle vetting so researchers stay focused on actual science. Networking with peer labs or industrial partners helps, as you learn which distributors deliver on both service and compliance. For private buyers, approaching reputable research suppliers and being transparent about the intended use opens the right doors.

A beginner might feel overwhelmed facing all this. The learning curve pays off. No legitimate seller minds your safety questions or hesitations about paperwork. In fact, if they get annoyed, that’s a bright red flag. At no point does the headache of cutting corners pay off. For deeper specialty or bulk uses, consider direct outreach to producers. Make sure the emails use official institutional addresses and explain your credentials up front.

Responsible procurement starts with education. If policies slow down the buying process, that’s good news for everyone wanting to maintain standards. Open dialogues between buyers and suppliers—plus support for transparency initiatives—make labs and workplaces safer. Specialty chemicals deserve respect, in how we store, transport, and buy them.

Whatever your project, stick with trusted distributers. Value the boring paperwork. It’s the only way to protect your research, your reputation, and your community.

| Names | |

| Preferred IUPAC name | tetradecanedioic acid |

| Other names |

1,14-Tetradecanedioic acid

Tetradecandioic acid n-Tetradecanedioic acid NSC 33279 |

| Pronunciation | /ˌtɛˌtreɪˌdeɪˌkeɪˈdiː.oʊ.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 7098-61-1 |

| Beilstein Reference | 1208731 |

| ChEBI | CHEBI:28804 |

| ChEMBL | CHEMBL14290 |

| ChemSpider | 19216 |

| DrugBank | DB04262 |

| ECHA InfoCard | 100.033.469 |

| EC Number | 206-535-4 |

| Gmelin Reference | 607416 |

| KEGG | C08297 |

| MeSH | D013761 |

| PubChem CID | 68573 |

| RTECS number | XD0425000 |

| UNII | 93P8DUD6VO |

| UN number | UN2811 |

| Properties | |

| Chemical formula | C14H26O4 |

| Molar mass | 258.39 g/mol |

| Appearance | White powder |

| Odor | Odorless |

| Density | 0.995 g/cm³ |

| Solubility in water | Insoluble in water |

| log P | 2.92 |

| Vapor pressure | <0.01 mmHg (20°C) |

| Acidity (pKa) | 4.89 |

| Basicity (pKb) | 11.35 |

| Magnetic susceptibility (χ) | -73.0e-6 cm³/mol |

| Refractive index (nD) | 1.465 |

| Viscosity | Viscous liquid |

| Dipole moment | 6.99 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 324.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1071.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -7907.7 kJ/mol |

| Pharmacology | |

| ATC code | D18AX02 |

| Hazards | |

| Main hazards | May cause respiratory irritation. |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. |

| Precautionary statements | P264, P280, P302+P352, P305+P351+P338, P362+P364 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | Flash point: 230 °C |

| Autoignition temperature | 439 °C |

| Lethal dose or concentration | LD50 oral rat > 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >5000 mg/kg (rat, oral) |

| NIOSH | NA3430000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 mg |

| Related compounds | |

| Related compounds |

Suberic acid

Sebacic acid Dodecanedioic acid Hexadecanedioic acid |