Dimethyl azelate didn’t just appear overnight. Its roots stretch back to advances in organic chemistry through the 20th century, particularly as scientists looked for ways to turn naturally occurring fatty acids into something more versatile and valuable. Early on, chemists cracked open the secrets of azelaic acid because industries needed molecules that could stretch their uses without blowing up the cost. Once they understood how to pull azelaic acid out of natural oils, making its dimethyl ester was the logical step. It was a classic combination of opportunity and practical need: chemists saw strong market potential in plasticizers and lubricants that could replace pricier or more volatile compounds. As demand grew for safer, durable materials in automotive and consumer goods, so did attention to building blocks like dimethyl azelate.

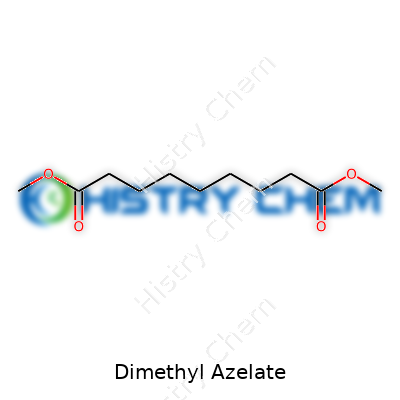

Dimethyl azelate stands out as the dimethyl ester form of azelaic acid, an aliphatic nine-carbon dicarboxylic acid. In real-world terms, it’s a clear, oily liquid, easily handled for various uses. Most people outside specialty chemical circles aren’t familiar with it, but inside labs and plants, it holds real importance. It bridges the gap between renewable plant-based chemistry and everyday high-performance products. Its C9 backbone provides flexibility, slipperiness and, crucially, decent thermal stability. These are not abstract perks; they translate directly to longer equipment life and less worry about toxic breakdown products. The molecule delivers a sweet spot: high molecular weight for physical toughness, a soft touch that doesn’t grow brittle over time, and a clean profile that avoids many regulatory headaches.

Dimethyl azelate takes the form of a colorless to pale yellow liquid, with a mild odor that reflects its fatty acid roots. It weighs in at about 1.01 g/cm³ at room temperature, and its boiling point comes close to 285°C. You can pour it fairly easily since it stays liquid way below freezing, and its vapor pressure runs low, meaning it doesn’t evaporate into the workspace air. It dissolves smoothly in most common organic solvents, though it shrugs off water. The fatty chain resists many aggressive chemicals, so dimethyl azelate won’t break down quickly, but the ester groups at each end give it the flexibility chemists love for making further modifications. These features open doors for end-users who want products that handle both mechanical and thermal loads in automotive, lubricants, or plastics fields.

Commercial suppliers usually set specifications that matter on the shop floor. Buyers look for purity, typically above 99%, minimizing moisture to avoid unwanted reactions down the line. The acid value stays low, keeping free acids in check, and color metrics help buyers confirm nothing has gone wrong during shipping or storage. Good labeling provides not just a CAS number (1732-10-1), but also full details of molecular structure, potential contaminants, and guidance on storage temperatures and shelf life. Labels these days aren’t just for compliance—they build confidence, especially as customers face tighter rules for traceability and workplace safety. The move toward digitization means more packaging now carries QR codes or scannable data to link directly with transport certificates, handling recommendations, and even disposal instructions.

Production of dimethyl azelate starts with natural fats and oils, most often from seed crops like castor or sunflower, which see oxidation or ozonolysis to produce azelaic acid. This process brings together oxidation chemistry—opening up unsaturated bonds to break the chain in just the right place—with efficient purification. Once technicians isolate pure azelaic acid, they use methanol in a process called esterification, often with acid catalysts like sulfuric acid, to turn both carboxyl ends of the acid into methyl esters. Heat, agitation, and precise control of reaction time make sure the resulting dimethyl azelate falls within the desired purity range and that side products or unreacted acid get washed away before final formulation.

The most talked-about feature of dimethyl azelate is the pair of ester groups at each end, which make the molecule accessible for chemical tweaks. Chemists use those points to graft new functionality or build bigger molecules—think of polyesters for tough coatings or advanced lubricants with tailor-made flow properties. You can hydrolyze the ester to recover azelaic acid or switch the methyl for larger alcohols to craft custom esters. For specialty needs, further functionalization on the chain, although less common, creates diversified materials: branched lubricants, surfactants, and plasticizers. Industrial process folks know these kinds of modifications can mean the difference between a product that barely makes spec and one that blows away performance targets.

Not everyone uses the same name on an order form. Suppliers and chemists may call it dimethyl azelanedionate, azelaic acid dimethyl ester, or simply methyl nonanedioate. In older European literature, you’ll see the name nonanedioic acid dimethyl ester pop up. For regulatory filings, the CAS number helps avoid confusion. Branding in industry circles sometimes introduces folk names, but the backbone—the nine-carbon chain with two methyl esters—remains clear no matter which name lands on a shipping manifest.

Users in manufacturing or labs pay close attention to how dimethyl azelate behaves during handling. Spills or direct skin contact don’t present extreme hazards, but getting it in the eyes or inhaling concentrated vapors in poorly ventilated spaces causes irritation. Storage in tightly closed containers, away from heat or open flame, keeps the product from degrading or posing unnecessary risk. Standard operating procedures rely on rubber gloves and goggles during large-scale handling. Material safety data sheets point out that the chemical breaks down into smaller fragments way above normal usage temperatures, but in most real-world environments, it stays safely inert. Emergency guidelines mirror those for other medium-chain esters: avoid open drains, scoop up spills with absorbent material, and ventilate affected areas to keep air quality within local regulations.

Dimethyl azelate works behind the scenes in a surprising list of products. Lubricant makers lean on it for its resistance to thickening and breakdown under pressure, giving machines a longer operational life and reducing the need for repeated oil changes. The plasticizers market makes good use of it in producing flexible polyvinyl chloride (PVC) items, especially when flexibility and low-temperature performance need a boost. It pops up in certain adhesives thanks to its tack-boosting and permanence, where stickers stay strong through hot, cold, and damp. In specialty cosmetics—fewer than most would guess—its parent acid sometimes finds use in treating skin conditions, though the dimethyl ester’s focus stays industrial. Outside of those arenas, ongoing research keeps pushing for new avenues, whether as a building block for biodegradable plastics or as a base component in advanced synthetic lubricants targeting electric vehicles.

The R&D spotlight currently shines brightest on sustainability. Chemical engineers and product designers share a common ambition: making familiar products less reliant on fossil resources and more on renewable feedstocks. Dimethyl azelate fits nicely here. Research teams in Europe, Asia, and North America have turned to enzymes that speed up fatty acid conversion under mild conditions, slashing energy costs and reducing secondary pollution. The rise of green chemistry has helped make dimethyl azelate from non-edible plant oils or even recycled biowaste instead of virgin petrochemicals. Papers from industry and academia focus on scaling up these methods, while patents increasingly cover novel uses for their unique chemical backbone, whether that means heat-resistant polymers or ultra-low-viscosity base oils for next-generation EV motors.

Scientists long ago established that dimethyl azelate does not behave like some infamous phthalate plasticizers or volatile aromatics that made headlines for health risks. Animal studies at high doses have pointed to mild and reversible skin or eye irritation, which sits in line with many fatty esters. Its low volatility and undetectable odor decrease accidental inhalation concerns, though, as with any chemical, chronic exposure via large-scale spills could cause environmental issues downstream. Regulatory reviews in the EU and US keep it on the safer side of restricted lists, but ongoing work watches for metabolites and the impact of breakdown products on aquatic systems. Through it all, the chemical has maintained a reputation as a lower-risk ingredient, making it especially suited for use cases where human or environmental contact sits front and center.

What grabs attention today is how dimethyl azelate dovetails with bigger trends in green chemistry and performance engineering. Products need to stand up to tougher regulatory scrutiny for non-toxicity and biodegradability, especially in applications like children’s toys, cables, or food packaging. The molecule’s fatty acid legacy appeals to those pivoting toward renewable carbon systems and closed-loop manufacturing. Advances in biotech and catalytic chemistry have made the conversion from seed oil to methyl ester both cleaner and cheaper, giving more players the chance to ditch older, cruder esters. As electric motors become the norm, demand for base fluids that won’t degrade or gum up under punishing conditions will only increase, and dimethyl azelate looks well-positioned to deliver on that promise. Expect to see its name in more patent filings, regulatory submissions, and perhaps even the consumer safety debates as industries keep shifting toward sustainable, high-performance chemistry.

Dimethyl azelate doesn’t usually show up in everyday conversations, but it finds its way into several products and processes people use without a second thought. This compound, made from azelaic acid and methanol, brings some unique traits that push businesses to put it to work in manufacturing and development.

Step into the fragrance industry, and you’ll see dimethyl azelate helping out as a fixative and carrier. This means it supports perfume notes, holding them steady so the scent lingers longer on the skin. Many luxury houses rely on similar esters for this reason—dimethyl azelate won’t overpower more delicate notes, so it balances formulas in ways a nose can appreciate. When I used to help friends select a scent, they pointed out how the best perfumes held on for hours, and chemistry like this lies behind that staying power.

Smoothing agents in personal care often get ignored, but dimethyl azelate makes its mark. It slips into lotions and skin creams, softening the formula without clogging pores or leaving a greasy layer. The cosmetics industry keeps looking for alternatives that don’t trigger reactions. Dimethyl azelate fits the bill in many hypoallergenic products. I’ve spotted labels listing it under “emollients,” so it brings a smooth feel that customers appreciate.

Manufacturers look for plasticizers that add flexibility to polymers. Dimethyl azelate stands out for its low toxicity and good compatibility with a long list of materials. Cables, flooring, and synthetic leathers rely on compounds like this to keep them supple. Flexible PVC, a common sight in construction, becomes easier to handle and lasts longer with plasticizers like dimethyl azelate. Having worked with flooring contractors, I’ve seen firsthand how quality and workability improve when the right plasticizer gets mixed in, saving time and trouble onsite.

Machine shops and auto manufacturers won’t make headlines for their choice in base oils, but they pay attention to what keeps engines and machines running smoothly. Dimethyl azelate brings stability at high temperatures and resists breaking down over time. Modern synthetic lubricants use esters like this to protect parts and cut down on engine wear. Car owners might not notice the difference at the dipstick, yet mechanics see fewer breakdowns and longer engine life, which boils down to less waste and lower maintenance costs over years of driving.

Sourcing sustainable ingredients matters more each year. Dimethyl azelate gets attention because azelaic acid can be made from plant oils like castor or sunflower. Leading chemical companies include it in “green chemistry” lines, aiming to lessen the impact of manufacturing on the environment. Researchers continue to study its long-term health effects, and current safety data paints a reassuring picture with proper handling. Agencies like the European Chemicals Agency track exposure and risks, pushing the industry to keep records transparent and safe.

Real change comes when industry experts, consumers, and regulators keep open lines of communication. Dimethyl azelate’s role keeps expanding as manufacturers hunt for better, safer materials. People want everyday products that perform well without health or environmental trade-offs, and compounds like this play a concrete role in moving the market in that direction. Direct experience with useful, adaptable chemicals like dimethyl azelate shows how even small shifts can ripple out, shaping healthier, more sustainable lives.

Dimethyl azelate often pops up on ingredient labels for skin creams, lotions, and even hair conditioners. Manufacturers favor it for its ability to soften skin and improve spreadability. Most users have no idea it’s there. I only learned about it while digging through cosmetic chemistry as a hobby, surprised by how many “chemically-sounding” names actually refer to mild and safe ingredients.

What matters most to consumers is safety. I’ve scoured papers from cosmetic science journals and regulatory notices. The Cosmetic Ingredient Review (CIR) panel, which brings together toxicologists, dermatologists, and scientific experts, has identified no major risks in normal use levels for dimethyl azelate. Skin irritation and allergic reactions remain rare in patch tests following standard concentrations. This isn’t an ingredient with a scary safety record or a history of major adverse reactions. It gets a “green light” in the eyes of experts.

European regulators list it as allowed for general cosmetic use, and U.S. bodies do not flag it for any particular concern. That isn’t a blank check—this ingredient still needs to meet manufacturing standards, and companies should make sure they are using high-purity raw materials. Trace contaminants or improper use could flip the script.

A growing chunk of customers researches every ingredient in their skin cream. People feel uneasy reading multisyllabic chemical names on a bottle, so transparency means more than just a green box at the bottom of a webpage. Full disclosure builds trust. Brands that clearly explain why they include dimethyl azelate, and share data about safety testing, do the public a service. I've reached out to brands myself and have been impressed by those who give honest answers, point me toward primary research, and put customer questions first.

Most people glide over lotions and never sense a problem. That said, no ingredient fits every person. A few with unusually sensitive skin might notice redness or discomfort—rare, but possible. My own testing, as someone with eczema, led me to avoid products with strong fragrances, not dimethyl azelate, but I always run a patch test for anything new. That’s simple advice: place a dab of the product on a small area and check for symptoms before full use. Doctors recommend this same approach for anyone with a history of skin issues.

Science doesn’t stand still. Cosmetic chemists keep looking for milder, better-performing alternatives. Brands worth supporting listen closely to dermatologists, invest in new safety research, and reformulate when better options show up. In my experience, companies that foster transparency and constant improvement earn loyal customers, especially those shopping with sensitive skin in mind.

Regulators, researchers, and cosmetics companies share the responsibility of protecting public welfare. Independent third-party testing and published findings support confidence for everyday consumers. I place trust in brands showing their science, welcoming questions, and funding research into long-term skin effects. Consumers have a seat in this process, too, by sharing honest feedback and raising questions about what goes on their bodies.

Dimethyl azelate stands out as a clear, colorless liquid with a faint, slightly sweet odor. Right away, it’s clear this compound won’t cause a mess like sticky or greasy alternatives. Pouring it, you’ll notice the viscosity sits a notch above water but doesn’t have the thickness of oils used in heavy machinery. At room temperature, it flows easily, making handling and measuring simple tasks for any laboratory or manufacturing worker.

Weighing about 1.01 grams per cubic centimeter, it doesn’t stray far from water in terms of density. If you pour a bit into a glass container, it forms a smooth layer without clinging to the sides more than expected. For safety, its flash point hovers around 130°C, so a hot environment isn’t very friendly to it. That high flash point limits fire risk but still means careful storage – nobody wants to invite trouble with hot plates or sparks nearby.

Its boiling point approaches 287°C, so reaching vapor phase in most environments is unlikely. This gives it a certain stability, something anyone working daily in processing or research can appreciate. It melts at around -2°C, so it can solidify if a workspace drops below freezing for extended periods.

Many esters can blend with a wide range of solvents, and dimethyl azelate fits right in. It dissolves well in organic solvents like acetone, ether, and chloroform. Try to mix it with plain water, results will disappoint. Tiny amounts dissolve, but big batches just float atop or form layers. This behavior matters for folks designing formulations in cosmetics, lubricants, or the flavors and fragrances industry. It won’t interfere with aqueous ingredients but blends seamlessly where organic solvents call the shots.

Experience in labs shows this chemical plays well in mixtures aiming for smooth, non-greasy textures. In the right context, it serves as a crucial base where unwanted thickening or separation can spoil the batch.

Chemically, dimethyl azelate carries two ester groups, thanks to its structure built from azelaic acid and methanol. This backbone gives it decent resistance to oxidation at room temperature, so it sits comfortably on shelves and doesn’t turn rancid quickly. Leave it exposed to strong acids or bases, and the story changes — those groups start breaking apart, reverting toward their starting acids and methanol. For long-term storage, keeping those corrosive agents at bay makes a world of difference.

No wild chemical behavior jumps out under standard industrial use. Spark it under a flame, and you get carbon oxides, so ventilation and masks around any open burn become important. Anyone preparing chemical syntheses or scale-up processes can expect predictable, safe reactivity, provided their routine safety steps remain rock solid.

You find dimethyl azelate at the core of certain plasticizers. That smooth viscosity and gentle reactivity fit just right, keeping plastics flexible without nasty breakdown products showing up. People tuning the scent profiles for fine fragrances pick it for its subtle sweet notes and solvent quality, blowing the doors open for new aromas. Lubricant creators rely on its slick feel and stability in heat, where greasy build-up or residue won’t fly.

Every property links back to its proven track record in consistency and reliability. Experts following strict formulation standards appreciate knowing its boiling point, solubility, and flash point through and through. Those handling it in busy industrial spaces value solid, actionable safety data – from melting characteristics to reactivity under heat or acid attack. Each trait supports broader goals in performance, worker safety, and high-quality finished goods.

Dimethyl azelate often turns up in a bunch of everyday items, hiding behind the chemistry that makes up lubricants, plastics, flavors, and perfumes. Behind its smooth performance lies a simple carbon chain that’s built to adapt. I’ve worked in labs where minor tweaks in production can change the quality of these materials—from how long a new engine oil lasts, to how a cleaning product smells. Knowing where these chemicals come from matters. Consumers and manufacturers both benefit if production stays efficient, sustainable, and precise.

Making dimethyl azelate usually starts with azelaic acid, a nine-carbon dicarboxylic acid that often comes from breaking down fatty acids like oleic acid. Oleic acid shows up in many vegetable oils—sunflower, olive, and even canola. Factories rely on ozonolysis, which uses ozone to split oleic acid into smaller fragments. Azelaic acid stands as one of those fragments, and from here, chemistry enters methylation territory.

Methylation means attaching methyl groups to the acid molecules. Technicians combine azelaic acid with methanol, often in the presence of an acid catalyst. This setup encourages the carboxylic acids to transform into their methyl ester forms—so out comes dimethyl azelate plus water as a byproduct. This whole process happens at high temperatures to keep the reaction moving. Afterward, separating the valuable dimethyl azelate from leftover materials demands distillation and purification. It might sound simple, but bit by bit, the purity levels and efficiency can swing based on catalyst quality, temperature accuracy, or the source of starting acids. Cutting corners leads to waste or off-quality goods, so good practices make a real difference.

Not every chemistry innovation makes headlines, but sustainability drives real change for chemicals with heavy industrial use. Sourcing azelaic acid from renewable plant oils marks a shift away from petroleum-based chemicals. Workers in facilities using feedstocks like sunflower oil have noticed energy requirements drop and waste decrease. In countries where agricultural waste goes unused, converting these resources into azelaic acid means less landfill and more revenue—both for farmers and refineries.

Even so, the process can generate emissions if not managed closely. Ozone, used in ozonolysis, reacts quickly and remains hazardous if not perfectly handled. Industrial safety demands top-notch equipment and training. Some companies push research to use less dangerous oxidants or find enzymes that break down fatty acids without ozone at all. I’ve followed teams who’ve replaced traditional acids with solid acid catalysts, which last longer and can be recycled, cutting chemical consumption. These steps move the whole chain toward greener chemistry—something that adds up, not just for investors, but for workers and communities near production sites.

The push for higher quality and safer processes never slows down. Stakeholders—from plant managers to product designers—talk openly about ways to recover methanol, reuse catalysts, or capture byproducts for use in new products. Younger chemists in the field regularly suggest small changes: a better distillation column here, tweaking the catalyst there, always learning from mistakes that cost time or resources. Moving toward closed-loop systems isn’t science fiction—it’s the future of how chemicals like dimethyl azelate keep factories running without creating more problems than they solve.

Anyone who’s worked with chemicals for a living knows storage rules aren’t just a formality. Small mistakes can lead to big headaches—costly spills, safety scares, or wasted product. Dimethyl azelate, known for its role in cosmetics and fragrances, deserves the same level of respect as any other specialty chemical. Years in a lab or warehouse have shown again and again that discipline with storage pays off in reduced problems later.

Dimethyl azelate doesn’t demand a freezer, but it responds badly to high temperatures. A cool, dry place helps avoid unwanted reactions. Temperatures above 30°C encourage the material to degrade or lose some of its beneficial qualities. In hot climates or during summer months, air conditioning or isolated, shaded storage can make the difference between a stable supply and a hazard.

Moisture will spoil many chemicals, and this one is no different. Water can trigger hydrolysis, which changes the chemical structure and affects quality. Desiccant packs and tight seals have proven themselves time after time on my own shelves, especially in humid storage rooms. Simple steps like checking for condensation or leaks cost almost nothing, but prevent expensive loss and contamination down the road.

Plastic or lined drum containers stand up well to dimethyl azelate. Some try glass for smaller quantities, but for larger batches, drum-grade plastics avoid both corrosion and breakage. Remembering to label everything clearly cannot be skipped. In busy supply rooms, a missing or smudged label can cause a mix-up that risks both safety and inventory accuracy. From first-hand mishaps, I can say that regular checks and re-labeling faded containers become habit for anyone who’s been burned before.

Dimethyl azelate’s flashpoint sits well above room temperature, but good ventilation always belongs in the plan. Fumes may not kick in until the material heats up, yet poor airflow raises long-term risks. A basic mechanical exhaust system or at least open grids above the storage area makes a real difference. Don’t store near strong oxidizers or acids—chemicals like nitric or sulfuric acid react violently. Fire-resistant cabinets earn their keep wherever volumes rise past a few liters, especially in businesses where flammable solvents sit close by.

Weekly inspections catch leaks, broken seals, old containers, or labeling errors. These walkthroughs aren’t just for the safety officer; every hand in the storeroom should spend a few minutes whenever collecting materials or restocking. During my own years running a production line, catching a cracked lid or sticky drum early always saved the company from loss and downtime. Spills might seem rare, but ignoring routine housekeeping means they’ll eventually happen—and the mess is never worth the few minutes saved.

Proper training matters more than the best equipment. Talking through correct handling steps with newer staff and emphasizing eye protection, gloves, and immediate cleanup means fewer surprises. Practicing the right steps for transferring and dispensing, including pump or siphon use instead of open pouring, minimizes both risk and waste. Once workers know their way around these rules, fewer slip-ups occur, and the workday runs smoother.

Every chemical comes with its own set of quirks. Dimethyl azelate’s are manageable with cool, dry storage, sturdy containers, solid labeling, regular checks, and steady training. Ignoring any one part opens the door to accidents or lost material. Over years in industry, the value of these habits proves itself each time trouble gets headed off before it starts.

| Names | |

| Preferred IUPAC name | Dimethyl nonanedioate |

| Other names |

Dimethyl nonanedioate

Dimethyl azelanedicarboxylate Azelic acid dimethyl ester |

| Pronunciation | /daɪˈmiːθəl əˈziːleɪt/ |

| Identifiers | |

| CAS Number | 1732-10-1 |

| Beilstein Reference | 793545 |

| ChEBI | CHEBI:77811 |

| ChEMBL | CHEMBL3185469 |

| ChemSpider | 14515 |

| DrugBank | DB14182 |

| ECHA InfoCard | 100.010.234 |

| EC Number | 207-399-7 |

| Gmelin Reference | 103238 |

| KEGG | C16576 |

| MeSH | D000603 |

| PubChem CID | 8126 |

| RTECS number | AT5250000 |

| UNII | O43E9E8L9S |

| UN number | UN1993 |

| Properties | |

| Chemical formula | C11H20O4 |

| Molar mass | 200.28 g/mol |

| Appearance | White to off-white crystalline powder |

| Odor | Mild, fatty odor |

| Density | 1.018 g/cm3 |

| Solubility in water | Insoluble |

| log P | 2.78 |

| Vapor pressure | 0.01 mmHg (20°C) |

| Acidity (pKa) | 8.83 |

| Basicity (pKb) | 2.9 |

| Magnetic susceptibility (χ) | -66.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.419 |

| Viscosity | 8.1 mPa·s (20 °C) |

| Dipole moment | 4.62 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 370.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -685.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –6147.1 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319 |

| Precautionary statements | Precautionary statements: P261, P264, P272, P273, P280, P301+P312, P302+P352, P305+P351+P338, P312, P321, P332+P313, P337+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Flash point | 140 °C (closed cup) |

| Autoignition temperature | 254 °C |

| Lethal dose or concentration | LD50 (oral, rat): >5000 mg/kg |

| LD50 (median dose) | LD50 (median dose) = 5000 mg/kg (oral, rat) |

| NIOSH | NIOSH: EM2975000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/m³ |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Azelic acid

Monomethyl azelate Diethyl azelate |