Long before nylon stockings and car seats, researchers eyed a colorless crystalline compound known for its tart flavor and easy solubility: adipic acid. Naming and isolating it from various plant extracts in the 19th century, chemists saw potential. By the early 20th century, pioneering work with oxidation of cyclohexanol and cyclohexanone birthed a scalable synthetic method. The commercial story really took off when nylon took center stage in fiber and engineering plastics; those first manufacturing plants opened the door to vast new markets. Production kept growing as scientists improved oxidation catalysts and discovered feedstocks that reduced waste and costs. Every time I walk past a factory or see a nylon rope, I think about the decades of quiet research that pulled this once-obscure chemical into the global economy.

Adipic acid comes from the family of dicarboxylic acids. It shows up as a white powder or crystals. Industry buys it in bags, drums, or bulk tankers. It finds its way into plant walls and gets synthesized in high-purity form for demanding polymer production. Pure adipic acid lands in plasticizers, resins, lubricants, and food additives. For the nylon fiber business, only the highest grades suffice—impurities turn up quickly in finished products. Lower grades still serve the chemical needs of cleaners, paints, and adhesives. Everyday applications in gel capsules, food flavoring, and even low-calorie sweeteners show the reach of this simple molecule.

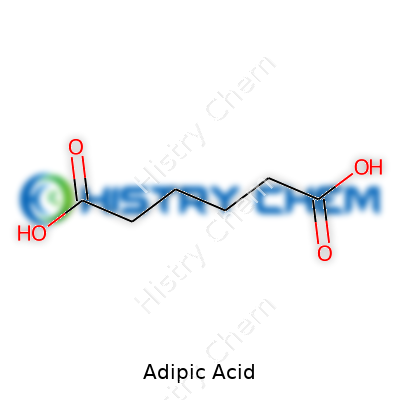

With a melting point near 152 °C and a boiling point beyond 330 °C, adipic acid doesn’t volatilize easily, making it reliable for hot processes. Solubility in water sits around 15 grams per liter at room temperature—enough to let it dissolve for most polymerization reactions but not so much that it leaks out of end use products. Chemically, it acts as a pretty straightforward acid, with two carboxyl groups spaced by a six-carbon chain. That spacing matters: it gives nylon 6,6 its particular strength and heat resistance. Adipic acid stays odorless and resists decomposition until heated above its melting point. Handling crystalline powders or granules, I’ve found the dust can stick to fingers and sometimes feels greasy, though it isn’t oily in the chemical sense.

Suppliers set tight specs for purity, including moisture content, iron, ash, and any trace organics. Typical grades boast purity above 99.7% and low color values. Modern labeling follows global requirements with clear batch numbers, production dates, and safety codes. In export, the harmonized system code and hazard class get printed near the net weight. Working with orders for polymers taught me to double-check for specification sheets—industrial users have little patience for off-grade shipments. GHS pictograms for irritants, handling precautions, and warehousing advice ensure safe use and proper inventory rotation.

Factories make adipic acid mostly by oxidizing a mixture of cyclohexanol and cyclohexanone with nitric acid, using copper or vanadium catalysts for better yields and lower byproduct formation. The early days saw lots of environmental headaches; nitrous oxide emissions haunted the air around plants. New processes capture or destroy these gases, addressing tighter regulations in Europe and North America. Some researchers and startup firms go after biobased routes, fermenting glucose or other sugars to intermediates like glucaric acid, which they then convert chemically. These newer methods haven’t replaced the old yet, but any reduction in fossil use draws an eager audience.

Adipic acid isn’t a one-trick pony. Almost every reaction involving carboxyl acids works here—amides, esters, salts, even anhydrides if conditions get hot enough. I’ve seen colleagues run dehydration steps to make cyclic anhydrides for specialty plasticizers. Direct reaction with diamines yields nylon salt, the real workhorse in synthetic fiber. Modifying with alcohols or amino compounds lets chemists design new surfactants or specialty polyesters. Some labs tweak the chain length or introduce side groups to tailor polymer properties for demanding gear or biomedical parts.

Ask for hexanedioic acid in European factories, and a worker wheels over a drum—adipic acid under its IUPAC label. Chemists sometimes use “1,6-hexanedioic acid,” “E355” in food contexts, or manufacturer labels like “Polyon 210” or “Dicarboxylic Acid No. 6.” This parade of names can slow down sourcing or regulatory compliance if you don’t cross-check documentation. Looking through supply contracts, I’ve seen plenty of confusion from outdated or regional synonyms; knowing the CAS number solves most headaches.

Good ventilation matters for any workspace handling adipic acid, even though it doesn’t vaporize fast. Dust can irritate eyes and lungs. Large plants keep explosion-proof dust collection onsite, especially at packaging or unloading points. MSDS sheets spell out safe exposure limits and necessary gloves, goggles, and dust protection. The compound doesn’t set off alarms as a carcinogen or environmental toxin at standard workplace levels, but spill cleanup rules call for careful containment and sweeping up residues to keep waterways clean. Regular training on first aid and chemical safety ensures both managers and plant workers stay informed amid changing standards.

The fiber and plastics sector draws huge volumes of adipic acid for nylon 6,6; every car, appliance, and carpet benefits from its strength and heat resistance. Polyurethanes rely on it to make tough, flexible foams for furniture and insoles. Food and pharmaceutical industries add small quantities as acidulants or gelling agents, often in clear beverages or chewable tablets. Even the world of specialty coatings, lubricants, adhesives, and paper sizing derives a portion of its performance from modified formulations based on this dicarboxylate. Looking back over product launches, I see companies turning to adipic acid to cut dependence on phthalates and other legacy additives now under environmental scrutiny.

Research labs keep searching for ways to improve yields, lower emissions, and replace fossil resources with biobased sources. One line of work looks at fermentation routes—engineered microbes convert cheap sugars to intermediates, cutting energy use from days of high-temperature nitric acid oxidation. Others explore new catalysis to reduce nitrous oxide, a potent greenhouse gas. Academic partners test catalysts and process conditions, sharing results with industry consortia that push cleaner production on a global scale. Biopolymers and compostable plastics beckon as endpoints, provided adipic acid can be manufactured at scale from renewables. Near my own community, startup pilots use wood residue streams and beet pulp as feedstocks, nudging biorefineries closer to commercial success.

Long-term studies on adipic acid underline its relative safety at levels typically seen in workplaces and foods, but chronic high-dose animal tests show kidney and stomach effects. Scientists monitor workers handling dust, and food safety panels maintain tight daily limits for consumption in beverages and processed snacks. Release to soil or water brings up the biodegradation rate—adipic acid breaks down quickly through environmental pathways, and tests confirm low risk of groundwater buildup. Still, continuous re-evaluation by regulatory authorities guards against surprises as new applications push usage higher or closer to sensitive populations. Several labs check for subtle toxin mechanisms and developmental impacts, aware that large-scale manufacturing always urges caution.

As global pressure mounts to remake chemicals from renewable sources, adipic acid finds itself on lists of strategic green building blocks. Companies line up incentives for microbial and catalytic breakthroughs that reduce carbon intensity, and policy pushes in the EU and Asia set ambitious targets for bio-based polymers. The challenge lies not only in making greener adipic acid but also in pricing it to win business against the established petrochemical chain. Research communities, startups, and old-guard manufacturers share patents and run pilot lines, spurred on by customers in apparel and automotive itching for a decarbonized story. The next wave of growth may ride on sustainable fashion, compostable textiles, and regulatory bans on older plasticizers. From what I’ve seen, those racing to scale up fermentation or waste-to-chemical approaches will shape not only the bottom line but the footprint for plastics and coatings for a generation to come.

Most folks who pull on nylon jackets, tie a pair of running shoes, or zip up a backpack rarely think about the chemistry involved. Adipic acid plays a huge part here. Factories around the world rely on this compound as a main ingredient to produce nylon 6,6. They take adipic acid, combine it with hexamethylenediamine, and boom—nylon polymer forms. This tough synthetic fiber appears in everything from carpet fibers to automobile airbags. The grip of nylon on the modern economy feels tight; in 2023 alone, nylon’s global market stretched beyond $30 billion, according to industry reports.

Adipic acid crops up in more places than just textiles. Look inside many household cleaning products—powder detergents especially—and you’ll spot it in the list of ingredients. Laundry powders use it to control pH and improve how well they clean. In my experience working at a local supermarket, shoppers grab hundreds of boxes each week. They probably never notice what goes into getting their shirts bright again. The food world taps adipic acid too. Think of those jiggling, tart gelatin desserts or some powdered drink mixes. Adipic acid gives foods a tangy bite and helps gels keep their shape. Food safety regulators in the US and Europe set strict limits so that its use in foods stays safe.

The construction crowd doesn’t skip over this chemical. Adipic acid fits into polyurethane production, a key material for insulation panels, foam cushioning, and sealants. In the past, families faced chilly drafts from old, single-pane windows. Updated polyurethane foam created with adipic acid reduces heat loss, saving homeowners money on energy bills. That effect matters not just for comfort, but for climate emissions too. Builders and architects talk a lot about creating efficient buildings. As the world pushes for greener solutions, insulation materials built using proven chemicals like adipic acid will likely play a bigger role.

Every silver lining comes with a cloud. The production of adipic acid throws off nitrous oxide, a greenhouse gas that packs a wallop, warming the atmosphere three hundred times more than carbon dioxide. Scientists and industry leaders know this, and some plants now use advanced filters or catalysts that limit those emissions. There’s steady progress; in recent years, European plants have slashed nitrous oxide leaks by more than 90%. Still, demand for nylon and polyurethane keeps the pressure high. Researchers actively search for new ways to make adipic acid from biological sources like sugar or plant waste rather than petroleum. These bio-based methods could shrink the environmental burden, though scaling up these experiments to serve bustling global markets looks tough.

My own take, after years watching family members in both foodservice and building trades, is that chemicals like adipic acid reflect bigger choices—comfort, convenience, and cost against health and climate. Society wants strong, affordable materials, but doesn’t want the world to overheat. Better transparency, strong regulation, and honest research can close the gap between what’s possible in a lab and what shows up on supermarket shelves or construction sites. Alternatives keep rolling out, but the footprint of old standards like adipic acid remains firmly planted in our lives.

Adipic acid carries the chemical formula C6H10O4. At a glance, those numbers might not seem interesting, but this small molecule has shaped the modern world more than many realize. Most people encounter it almost daily, mostly without a second thought, especially if they ever zip up a nylon jacket or use synthetic carpets at home. The backbone of adipic acid allows it to connect with other chemicals to create things like nylon 6,6, a staple in textiles and plastics.

Industries crank out millions of tons of adipic acid every year. Production involves oxidizing cyclohexanone or cyclohexanol with nitric acid. Each step in the process matters beyond chemistry textbooks. A side product of this process, nitrous oxide, contributes to climate change almost three hundred times more than carbon dioxide. This hidden cost brings up a genuine dilemma; how do we keep up with demand for strong, versatile materials without ignoring environmental consequences?

I’ve spent enough time peeling nylon candy wrappers and tying up gear with tough nylon rope to appreciate how reliant day-to-day convenience is on chemical formulas like C6H10O4. My curiosity started with a college chemistry textbook, tracing each atom’s role from paper diagrams to the real world of clothing, car interiors, and sports equipment. Every time that zipper slides or a sidewalk holds up under traffic, I remember adipic acid is doing much of the heavy lifting.

Deep down, it’s clear there’s no running away from tough questions about impacts. Those nitrous oxide emissions aren’t a footnote—they shape air quality and the warming planet. Over the past decade, I’ve seen researchers get serious about recyclability and green chemistry. Scientists have managed to develop routes that rely less on crude oil and generate a much smaller emissions footprint. Plant-based methods and even low-impact biotechnology are showing promise, but none of them have scaled up enough to overhaul the current petrochemical system.

Investment in new processes can make a difference. Some companies are teaming up with universities to test catalysts that cut emissions in half, or experimenting with renewable starting materials instead of crude. This isn’t just good press; it’s crucial for keeping everyday products affordable and available in a world under pressure from climate change.

As someone who grew up watching more and more synthetic materials replace natural ones at home and on store shelves, it’s obvious how intertwined modern life and inventions like adipic acid have become. The formula C6H10O4 might look dry and technical, but what we do with it and how we make it will shape cities, homes, and natural landscapes for years to come.

Adipic acid pops up in lots of products, from nylon and plastics to food acidulants and flavorings. Over the years, I’ve run into it often—sometimes in labs, sometimes on the factory floor. In each setting, someone always brings up its safety. Not everyone who works with chemicals holds a PhD, so it matters to break things down for folks who might find themselves handling a white, grainy powder, wondering what it can really do.

Let’s get real—adipic acid doesn’t rank with the most dangerous chemicals out there. It doesn’t blow up, and it doesn’t eat through your skin like a strong acid. Still, I never reach for a scoop of any chemical without checking what happens if it finds its way into your eyes, throat, or lungs. Experts like OSHA flag adipic acid as an irritant. Touch your eyes or breathe in its dust, and you might feel burning, maybe some coughing or sneezing. People with allergies or wheezing should pay extra attention.

Science gives us numbers to watch. According to the Hazardous Substances Data Bank, a bit of powder on the skin can cause rashes after a while. Getting it in your eyes stings—a lot. Inhaling heavy dust raises the chance for a scratchy throat and runny nose. In my work, spills usually mean minor irritation, not life-threatening situations, but that doesn’t mean ignoring basic safety. Over months or years, repeated contact could start to add up, even if no one is clocking out early after one bad shift.

People sometimes roll their eyes at protective gear. But no one argues much after dust gets blown into their nose or lands in the wrong spot. I’ve seen seasoned workers who still think gloves and goggles are overkill, at least until they rub their eyes by accident. Goggles, gloves, a dust mask. That’s simple protection. Clean up spills with damp cloths, not brooms that spread the powder into the air.

Eating or drinking near processing lines sounds harmless, but that’s where accidents usually start. Handwashing stations work better than warning signs. Ventilation matters more as you move up to industrial scale. I’ve watched operators ignore local exhaust, until they see the dust cloud themselves.

Accidents happen. Eyes: flush with water, quick and steady. Skin: rinse it off. Inhaled too much: step outside or find clean air. Anyone gets sick or shows an allergic reaction—don’t tough it out. See a medic.

Adipic acid isn’t the villain of the storeroom, but it isn’t sugar or flour, either. Respect goes a long way. I’ve worked in places where safety got treated like a checklist—until someone got hurt. The sites where people stay healthy all take the same short list seriously: good gear, clean habits, practical first aid, and no shortcuts when moving or mixing the stuff.

At the end of the day, reliable information builds trust. People handle chemicals with confidence once they know what matters and see why the right habits pay off. Real knowledge doesn’t scare—it gives everyone a safer shot to earn a living and go home healthy.

Almost everyone uses something touched by adipic acid. Most folks don’t spot the stuff on store shelves, but take a look at your closet. Adipic acid goes straight into making nylon—especially nylon 6,6 fibers. These fibers show up in all sorts of clothing, carpets, and car parts. I remember my first road trip, packed into a car full of nylon-based seatbelts and interior fabrics. The strength, stretch, and durability come straight from the chemistry of adipic acid.

Over 60% of adipic acid turns into nylon every year. Not much else hits numbers like that for any chemical or fiber. Clothing manufacturers and automotive suppliers both trust the fiber’s resistance to abrasion and easy dyeing. If you’ve ever wondered why modern tents or outdoor jackets handle rough weather, a chunk of the credit goes to adipic acid’s role in the nylon blend.

Old mattresses used to sag fast, leaving us sore by sunrise. With polyurethane foam, sleeping and sitting got comfier. Makers of mattresses, sofas, and car seats turn to adipic acid because it strengthens flexible foams. That means fewer dents, less sag, and longer-lasting comfort.

The chemical connects molecules so foam holds its bounce. As someone who’s lived in both cramped dorms and furnished apartments, the difference between generic foam and the good stuff becomes obvious. Nobody asks what’s inside—just that the cushions still spring back after months of wear.

Adipic acid sneaks into processed foods as an additive—usually as an acidity regulator. Table jellies, drinks, even powdered drink mixes use small amounts to tweak tartness. I remember tasting the difference in lemon-lime drinks from big-name brands. That kick isn’t just citrus or sugar, but a touch of adipic acid balancing everything out.

Regulatory bodies like the FDA check and approve this use, so it’s safe within allowed limits. The taste matters, and so does shelf-life. Without balancing pH, you’d see drinks spoil faster or jellies turn strange.

Plastic films, coatings, and adhesives count on adipic acid. It reacts with other chemicals to keep plastics flexible and stable. This comes out in things like wire coverings and flexible wrappers. Electricians and cable manufacturers use products plasticized with adipic acid because wires stay bendable even in cold weather.

Coatings and sealants in construction sometimes feel like background noise in big projects, but they keep out water and protect surfaces. After a hurricane hit my neighborhood, repairs meant new window seals and coatings—many made from adipic acid-based resins. Turns out, the compounds stop water leaks and UV damage better than old-school products.

You can spot adipic acid in many cleaning powders and liquid detergents. It softens water and helps detergents do their job. Laundry day in my house involves keeping whites white, not gray. Builders in detergents give a fighting chance against mineral stains, often using adipic acid at the base.

Synthetic lubricants also turn to the chemical, especially for tough machines or high-stress engines. The reliability of these lubes often comes from the stability that adipic acid brings into the final mix, supporting heavy machinery that keeps factories running smoothly.

The world produces millions of tons of adipic acid each year—leading to questions about sustainability. Industry researchers have put more focus into green manufacturing and waste reduction. Bio-based routes from plant sugars already show promise compared to fossil-based production. The chemistry remains tricky, but market demand and regulations have both pushed innovation.

Many industries that rely on adipic acid look for ways to shrink environmental impact without giving up the performance everyone takes for granted.

If you’ve ever worn nylon or used automotive parts, you’ve brushed up against adipic acid, even if you didn’t spot it on a label. Nearly every seed of nylon, especially nylon-6,6, relies on adipic acid during production. It’s also tucked inside polyurethane foams, plasticizers for PVC, and even some food additives. You find it hiding in baking powder as a tart-tasting acidulant. Turning out that much adipic acid—over 3 million metric tons per year, according to the International Energy Agency—calls for efficient, reliable processes. But efficiency sometimes comes at a price for health and the planet if we’re not paying attention.

Factories make adipic acid from petrochemical feedstocks. Usually, the process starts with cyclohexane, a liquid taken from crude oil. Producers oxidize cyclohexane in big reactors using air. This step produces a mix of cyclohexanol and cyclohexanone, sometimes called KA (ketone-alcohol) oil. To create adipic acid, this mix goes through another round of oxidation, often with nitric acid.

During this second stage, things get dicey. Besides adipic acid, the reaction spits out a fair amount of nitrous oxide, a greenhouse gas about 300 times more potent than carbon dioxide. This side-effect sticks out as a black mark on an otherwise useful product. A handful of chemical makers now use catalysts and tighter controls to gather up excess gases and convert them before they hit the air. But many adopters haven’t moved over yet, so emissions keep climbing.

With a chemical reaction scaled up to millions of tons, small improvements mean a world of difference. Many researchers tackle nitrous oxide at the source, hunting for milder oxidizers or switching up the chemistry to cut byproducts. Some now look at bio-based adipic acid routes, starting with sugar—corn, beets, even wood chips. Early efforts used engineered yeast, tweaking their DNA, but struggles with yield and cost keep the industry grounded in old habits.

Europe’s aggressive emissions targets have pushed several plants to invest in nitrous oxide abatement tech. I’ve seen cases where companies install specialized catalysts or thermal reactors right on the site, breaking down gases before they slip out. In my experience visiting such plants, the upfront headache pays back over time—not just in lower emissions, but in the goodwill of buyers who value climate-focused brands.

A true pivot will take partnerships across supply chains. Downstream users, like makers of nylon, have real sway: they can pressure vendors for greener options and agree to absorb a modest premium for clean-source adipic acid. On the research side, government grants can grease the wheels for pilot plants exploring sugar-based production, giving startups the breathing room to outcompete fossil-based rivals.

Everyone along the chain, from the plant worker to the end consumer, benefits when the industry tackles these issues head-on. Adipic acid doesn’t just touch textiles or auto parts—its production leaves a mark on air and water. Chemical makers have options for cleaner production, but scaling them up takes buy-in and a willingness to put long-term health above short-term cost. Transparency helps, too. If brands and retailers ask the tough questions, improvement won’t stay in the slow lane.

| Names | |

| Preferred IUPAC name | hexanedioic acid |

| Other names |

Hexanedioic acid

1,4-Butanedicarboxylic acid Adipinsäure Acidum adipicum |

| Pronunciation | /ˈæd.ɪ.pɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 124-04-9 |

| 3D model (JSmol) | `/JSmol/viewer/?modelid=Adipic_acid` |

| Beilstein Reference | 1205290 |

| ChEBI | CHEBI:30794 |

| ChEMBL | CHEMBL962 |

| ChemSpider | 503 |

| DrugBank | DB01877 |

| ECHA InfoCard | 100.007.703 |

| EC Number | 204-673-3 |

| Gmelin Reference | 10445 |

| KEGG | C08373 |

| MeSH | D000255 |

| PubChem CID | 196 |

| RTECS number | AR6820000 |

| UNII | V43897061Z |

| UN number | UN2076 |

| Properties | |

| Chemical formula | C6H10O4 |

| Molar mass | 146.14 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.36 g/cm³ |

| Solubility in water | 14 g/L (20 °C) |

| log P | 0.08 |

| Vapor pressure | 0.13 mmHg (at 25 °C) |

| Acidity (pKa) | 4.41, 5.41 |

| Basicity (pKb) | pKb ≈ 10.74 |

| Magnetic susceptibility (χ) | -7.9e-6 |

| Refractive index (nD) | 1.439 |

| Viscosity | 0.0153 Pa.s (at 150°C) |

| Dipole moment | 1.12 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 153.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1357 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3351 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | A16AX10 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS05 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | If exposed or concerned: Get medical advice/attention. Store in a well-ventilated place. Keep container tightly closed. Store locked up. Dispose of contents/container in accordance with local/regional/national/international regulations. |

| NFPA 704 (fire diamond) | 1-1-0-W |

| Flash point | 196 °C (385 °F) |

| Autoignition temperature | 405 °C (761 °F) |

| Lethal dose or concentration | LD50 Oral Rat 5700 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 5700 mg/kg |

| NIOSH | AU4025000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Adipic Acid: "5 mg/m³ (OSHA TWA) |

| REL (Recommended) | 50 mg/m³ |

| IDLH (Immediate danger) | 1000 mg/m3 |

| Related compounds | |

| Related compounds |

Succinic acid

Glutaric acid Pimelic acid Sebacic acid Hexamethylenediamine Nylon 6,6 |