Chemical innovation rarely happens in a vacuum, and 2-Butyne-1,4-diol stands as a product of necessity and ingenuity. In the mid-20th century, companies and scientists searched for better intermediates that could serve in everything from polymer synthesis to pharmaceuticals. Amid these efforts, 2-Butyne-1,4-diol found its place thanks to its unique structure and versatility. Back in the 1960s, its production offered a bridge between the petrochemical boom and the need for reactive intermediates that could open doors to new products. Manufacturers and research labs began scaling up its production not out of curiosity, but because their customers needed chemicals that could pivot easily into diverse end products. As new applications emerged, the story of this diol tied together changing industrial landscapes and the push toward more controlled synthetic processes. Today, companies still draw inspiration from those origins, trying to drive more sustainable and efficient routes for making and using 2-Butyne-1,4-diol.

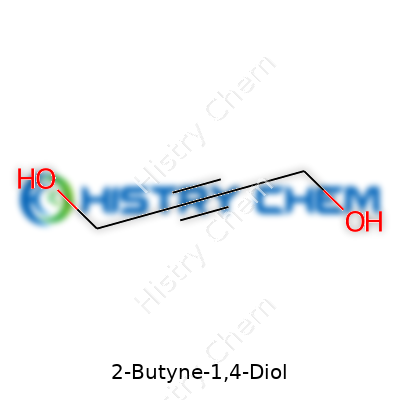

Also known as Bytynediol, 1,4-Butynediol, or But-2-yne-1,4-diol, the compound features prominently on lists of key alkyne diols. The truest value of this chemical lies in its adaptability; from polymer chemistry to specialty solvents, it often plays the role of both a starting material and a transformative reagent. Its identity, marked by the formula C4H6O2, represents not only a functional group rich in reactive potential but also a building block where chemists can carve new routes toward innovative materials.

2-Butyne-1,4-diol catches attention with its colorless to light-yellow crystalline appearance. You can tell a lot about its handling and storage just by looking at its melting point, which sits around 58°C. It dissolves well in water and a wide spread of organic solvents, such as ethanol and acetone, which means you won't run into trouble incorporating it into diverse formulations. That triple bond in the center (an alkyne) sets it apart from saturated diols. This doesn’t just shape its physical behavior; it also opens the door to a long list of downstream chemical reactions. The compound's relatively low vapor pressure and minimal odor don't scream for special attention in the lab, but handling it at scale means keeping an eye on the details — its reactivity climbs in the company of strong bases or acids. Its boiling point around 235°C (decomposes) reminds everyone that you need to know your conditions when heating or distilling.

A typical supplier sells 2-Butyne-1,4-diol with an assay over 98%, a water content often less than 0.5%, and minimal impurities such as heavy metals or chloride ions. Labs and factories rely on precise labeling that details batch number, date of manufacture, and full chemical identifiers. These details don’t just help with traceability; they honor the safety and consistency needs of downstream users who can’t afford mystery ingredients. Many facilities insist on shipments in tightly sealed HDPE drums, protected from direct sunlight or heat, which shows how even the packaging choices for a chemical like this reflect hard-learned lessons about purity and shelf life. Material Safety Data Sheets, offered with every batch, fill in the critical details to keep workers safe from start to finish.

In the early days, companies leaned on multi-step syntheses drawn from old-school acetylene chemistry. Commercial operations tend to start with acetylene, which reacts with formaldehyde in the presence of copper catalysts, leading to the formation of 2-Butyne-1,4-diol as the key product. This process often runs in aqueous solution, keeping conditions controlled and manageable. The elegant part lies in its efficiency: high selectivity, relatively good yields, and the ability to tune operational variables to squeeze every bit of product out of the starting materials. Scaling up from flask to reactor creates its own headaches—a batch that runs smoothly at a liter scale might behave unpredictably when fed by the ton, which is why field experience and careful parameter tracking make all the difference.

The backbone of 2-Butyne-1,4-diol begs for creative chemical engineering. The alkyne group stands out for hydrogenation, which converts the compound into either the trans- or cis-2-butene-1,4-diol depending on catalyst and process settings. Reduction can strip away the triple bond altogether, leaving behind 1,4-butanediol—a valuable ingredient in everything from plastics to solvents. The presence of both terminal and internal functional groups also welcomes halogenation, oxidation, and even cyclization reactions, each route producing compounds with their own uses in advanced materials or pharmaceuticals. Modification doesn’t just stop at the bench; companies often drive innovation by tweaking reaction parameters to enhance product selectivity, purity, or downstream compatibility.

Chemists and plant workers soon learn not to take safety for granted. 2-Butyne-1,4-diol, while less notorious than some alkynes, still brings significant hazards. Direct skin or eye contact can cause irritation; on inhalation, it may trigger headaches or nausea. Industrial practice demands handling it in well-ventilated areas, using gloves, goggles, and protective clothing without exception. The substance doesn't rank among the most volatile or instantly toxic, but its reactivity in combination with acids, bases, or oxidizers means emergency plans matter. Storing it away from incompatible substances and at stable temperatures protects not only the chemical itself but also the safety of everyone nearby. Every spill or mishap tells the same lesson: controls and training are less about regulatory box-checking and more about protecting lives and property. Facility managers usually keep spill kits close and reinforce response drills so mistakes don’t turn into disasters.

You find 2-Butyne-1,4-diol playing a lead role in a surprising range of industries. It acts as a precursor for specialty polymers and resins, where its reactivity shapes the structure and performance of the end product. The compound features in the synthesis of vitamin B6 intermediates, showing how chemical supply chains link basic chemicals to essential medicines. In the world of electronics, 2-Butyne-1,4-diol steps into plating solutions and surface treatments, helping deliver the conductivity or heat management that modern devices need. Textile manufacturers value its function as a cross-linking agent for improving water and chemical resistance. It even lends itself to chemical grouting and specialty coatings, demonstrating how small-molecule chemistry can drive innovation far from the lab benches where it was first studied.

Academic labs and industrial R&D groups treat 2-Butyne-1,4-diol both as a test case for reaction development and as a platform for new product discovery. Continuous work aims to improve synthetic yields, cut down on hazardous byproducts, and find milder or greener catalysts. Recently, research has focused on biocatalytic and electrochemical routes, with the goal to reduce the environmental footprint of its production. In medicinal chemistry, derivatives based on its structure show promise as scaffolds for new drugs as well as modified monomers for advanced materials. As a field chemist, I’ve seen research groups puzzle over how to coax better selectivity from familiar reactions, always balancing the push for innovation against the daily demands of production and safety.

The health impact of 2-Butyne-1,4-diol remains a subject of serious investigation. Acute exposure studies in animals have shown dose-dependent effects on the nervous and respiratory systems, which makes sense given the molecule's reactivity. Chronic exposure, even at low doses, can lead to cumulative issues, so regulatory agencies call for tight limits in workplace air and strict waste handling guidelines. Companies run regular air monitoring and offer medical screenings for workers who handle the substance frequently, which aligns with a broader industry move to prioritize occupational health. While the compound hasn't become a byword for toxicity, the historical record shows enough adverse incidents to fuel rigorous and ongoing safety reviews. Environmental fate research has also raised red flags about aquatic toxicity, pushing regulators to require careful containment and effluent treatment.

The future for 2-Butyne-1,4-diol looks tied to the push for greener, more efficient chemical production. As industries pivot toward sustainable synthesis, the race is on to find bio-based feedstocks or routes that cut out high-energy steps and hazardous reagents. New catalytic systems—especially those drawing from enzymes or recyclable metal complexes—offer hope for safer and more economical production. At the same time, markets like electronics and high-performance polymers continue to hunger for reactive intermediates with the versatility and functional power this diol brings. Demand could surge if ongoing research nails down new applications in pharmaceuticals or specialty materials, especially where performance hinges on precise molecular structure. As chemists learn more about reducing health and environmental risks, both the processes and applications of 2-Butyne-1,4-diol will likely get safer, cleaner, and more deeply woven into emerging technologies. Every breakthrough in synthesis or safety widens the horizon, making this not just a story about a single molecule, but about chemical progress itself.

2-Butyne-1,4-diol isn’t a household name, but most people come across products or processes shaped by this chemical. It looks like a simple oily compound, yet it pops up in some of the most recognizable corners of modern manufacturing. In my work with industrial chemistry teams, I’ve seen how 2-Butyne-1,4-diol becomes a quiet asset for several sectors. Factories don’t stock it in bulk without good reason. This compound saves time and cost in places where efficiency really counts.

Polymer companies often use 2-Butyne-1,4-diol to build specialty plastics. This compound reacts in unique ways with other materials, adding strength or flexibility where needed. Think of certain high-end adhesives or elastic fibers — those rely on chemical reactions started by molecules like this. During visits to polymer plants, engineers show how avoiding weak spots in products keeps claims low and customers happy. They emphasize the importance of raw materials that deliver reliable structure in their finished rolls and sheets of plastic.

2-Butyne-1,4-diol plays an important role in electroplating, especially for printed circuit boards. It acts as a leveling agent, which means it helps deposits even out during metal coating. Anyone who has looked inside a computer or smartphone has seen the results. Getting a smooth copper layer means less risk of short circuits. In hands-on production, it’s clear good leveling reduces rework and scrap. Facilities running 24/7 watch their chemical additives carefully because small changes can disrupt entire production runs.

Research teams working on pharmaceuticals use 2-Butyne-1,4-diol to synthesize key ingredients. Every molecule matters in drug chemistry. Streamlined synthesis processes keep costs down for manufacturers and patients alike. I’ve worked with pharmaceutical chemists who pick this compound to help create molecules that would be tough to make otherwise. In textiles, this chemical helps dye fixatives perform better, making colors stick to fibers more effectively. Clothes resist fading longer and keep their appeal.

In chemical laboratories, 2-Butyne-1,4-diol enables reactions under milder conditions. As chemists push for greener practices, such catalysts help limit energy use and hazardous byproducts. During some of my own trials, switching to this compound trimmed hours off reaction times and improved yields. That translates to less waste and safer working conditions, which regulatory inspectors always notice.

Problems do show up. Exposure to 2-Butyne-1,4-diol can irritate skin and eyes, so industrial users enforce strict safety protocols. Disaster strikes quickly if someone skips gloves or ventilators. Environmental rules keep getting tighter, especially for chemicals that linger in waste streams. My experience on plant floors tells me simple actions — like closed systems and recycling streams — help reduce both health risks and environmental damage. Some producers now research safer alternatives, but for now, few chemicals match its mix of performance and affordability.

In the next decade, as manufacturers look for greener processes, companies may lean on renewable sources or new synthesis routes. Teams in both academia and industry keep searching for replacements that hold up in tough conditions. Chemists, engineers, and plant managers can learn from each other. Being open about best practices and new findings helps everyone avoid past mistakes and build safer workplaces.

Spend enough time in a chemistry lab, and stories pile up about small mistakes turning into big problems. Take 2-Butyne-1,4-Diol. It looks deceptively clear, but it carries serious risks. The chemical does a lot in industry—used in textiles, coatings, pharmaceuticals. It can also burn skin, irritate lungs, and reacts pretty hard with strong oxidizers. You just can’t drop your guard around it.

Splash 2-Butyne-1,4-Diol on your skin and pain comes quick. Eyes cry out, nose stings, and your hands start to redden. Handling this chemical feels like a chemistry lesson in caution every time. One small spill can linger on a bench, and a little fume in your lungs brings coughing that sticks. The chemical also likes to mix poorly with others—especially acids and oxidizers—leading to surprise reactions that nobody needs.

Lab coats and gloves aren’t just for show. I learned early to trust that simple barrier. Nitrile gloves, never bare hands. A full face shield or splash goggles protect eyes. Synthetic fibers, like polyester, provide a shield for your skin; cotton alone just isn’t enough. Anything less, and this diol will find a way in—no one forgets chemical burns.

One of the biggest missteps comes from working with this compound outside a fume hood. I remember a colleague insisting it didn’t smell much—until he spent the afternoon coughing. Fume hoods cut exposure by keeping vapors away from your nose and lungs. Airflow in a lab matters, but only a good hood keeps the fumes managed. Never bring 2-Butyne-1,4-Diol to a crowded bench or small space.

This isn’t a chemical you leave just anywhere. 2-Butyne-1,4-Diol prefers cool, dry spots, locked away from acids, oxidizers, or heat sources. I once saw a small container left by a radiator—the next morning, the cap had warped and liquid pooled below. Always double-check lids and labels. Spills need quick, deliberate action: soak up with inert absorbents like vermiculite, then bag everything for disposal. Tossing rags in a regular trash can risks a fire.

Few things replace a habit of careful practice and real training. Every time a new person enters the lab, a walkthrough makes a difference. People skip steps when they get too comfortable, but one accident wakes up the whole team. Proper SDS review, clear labeling, and buddy checks on PPE have prevented more than one disaster in my experience. Rely on routines and peer checks instead of memory.

There’s always room to make things safer. Investing in newer containment systems, better spill kits, and thorough signage gives everyone fewer excuses to cut corners. Everyone wants to get the job done, but staying disciplined keeps you around to work another day. Bringing up safety in every meeting and rewarding careful handling goes farther than lectures. The right attitude, built on respect for real risk, keeps the lab running strong.

2-Butyne-1,4-diol stands out in the world of chemistry for its dual role as both an alkyne and a diol. Instead of hiding behind complicated terms, this molecule presents a structure that sparks curiosity. At its core, 2-Butyne-1,4-diol carries the formula C4H6O2. To picture its skeleton, imagine a short chain of four carbon atoms, with a triple bond connecting the two in the middle. Hydroxyl groups (–OH) anchor themselves at either end of the chain, giving it a set of chemical handlebars that make it more reactive than most straight-chain alkynes.

The specific layout looks like this: HO–CH2–C≡C–CH2–OH. That triple bond in the center divides the molecule, and those hydroxyl groups open opportunities for it to form bonds in a whole range of transformations.

In laboratory settings, this structure becomes a reference point for students learning about functional groups. The presence of both a triple carbon-carbon bond and two terminal alcohol groups allows chemists to explore reduction, oxidation, and polymerization reactions. Real-world uses often build from these reactive sites.

2-Butyne-1,4-diol shows up in some surprising places. Producers of pharmaceuticals and specialty chemicals value the molecule for its flexibility. It serves as a starting material in synthesizing products like vitamins (E and B6, among others), corrosion inhibitors, and herbicides. The synthesis of vinylbutanediol and other fine chemicals draws directly from its straightforward, yet unique, structure.

From experience working in a lab, the hands-on reality guides much of its importance. Triple bonds don’t shy away from hydrogenation, so 2-butene-1,4-diol springs out of reactor vessels from straightforward reduction. The attached hydroxyls let it slip easily into other reactions, sometimes acting as a bridge in multi-step synthetic projects. Chemists chasing novel molecules often begin with small, multi-functional building blocks like 2-butynediol.

In polymers, 2-Butyne-1,4-diol’s ability to engage in addition reactions helps create specialty resins and coatings, often used where flexibility and strength matter. For everyday consumers, most interactions remain invisible, yet the impact runs throughout electronics, automotive manufacturing, and medical supplies.

Handling 2-butynediol brings up important lessons in chemical safety. Like many alkynes and diols, this compound irritates the skin, eyes, and respiratory system at low doses. Proper ventilation matters. Safety goggles and gloves remain standard equipment—a practice drilled into anyone who has spent hours prepping glassware and adjusting pH meters. Industrial-scale operators further depend on local regulations and regular training to reduce exposure risks.

Production often takes cues from green chemistry, driving a search for less hazardous starting materials and milder reaction conditions. Embracing catalysts that reduce energy use and finding recycling options for reaction by-products is more common now. Facilities earning public trust usually show a record of spill containment and responsible disposal of reactor washings.

Effective protection comes from concrete steps: airtight storage, quick cleanup protocols, and personal protective equipment. Researchers and manufacturers track airborne levels, especially during large runs, using routine monitoring. Pursuing greener synthesis looks forward to enzymatic or bio-based strategies, slowly gaining ground as technology levels up.

2-Butyne-1,4-diol has a familiar structure—four carbons, a triple bond, two hydroxyl groups—but the impact stretches far. From lab benches to factory floors, respect for its reactivity and a commitment to responsible use provide a model for handling similar specialty chemicals in the future.

2-Butyne-1,4-diol doesn’t often appear in everyday conversation, but for anyone managing an industrial site, laboratory, or any facility that handles chemicals, familiarity with its storage could prevent major headaches. From my time working in a chemical plant, sloppy storage led to damaged equipment and more than a few safety discussions nobody wants to sit through. This stuff has value across polymer, pesticide, and fine chemical industries—but its benefits vanish quickly if mishandled.

Working with solvents and diols shaped my respect for proper storage. 2-Butyne-1,4-diol can ignite, react with oxidizers, and irritate skin, so tossing it on a shelf doesn’t cut it. I remember one cold morning where condensation ran down a mislabeled drum. The label fell off, turning safe storage into a guessing game. Every label, drum, and container matters for both safety and regulatory compliance.

The best practice always keeps moisture and direct sunlight away. Water can break down the chemical, and sunlight speeds up that process. I’ve seen storerooms with covered windows and low humidity, all because one leak turned a routine inspection into an emergency cleanup.

So, storage areas stay cool, usually below 30°C. Inadequate ventilation means stray fumes quickly become health risks. Without proper airflow, one mix-up or spill lingers long after cleaning. Facilities I trust always run exhaust fans and keep storerooms well-marked and accessible only to trained staff.

I once watched as a delivery arrived in the wrong type of drum—painted steel, not polyethylene or lined steel. Within days, signs of corrosion appeared. 2-Butyne-1,4-diol reacts with some metals over time, leading to leaks or worse. Polyethylene and compatible lining materials stand up best. Tight sealing prevents both evaporation and accidental contamination from dust, dirt, or other substances.

Labels make or break chemical management. I’ve worked with teams where bold lettering, hazard warnings, and handling instructions were standard. No one trusted a faded, smudged label—unlabeled containers simply meant an expensive disposal. Segregate away from oxidizers, acids, bases because shelf space comes cheap compared to fire damage or regulatory fines. Dedicated cabinets or containment trays catch drips and help catch mistakes before they matter.

Rotating stock with a “first-in, first-out” mindset reduces expired batches. I once opened a long-neglected drum, only to find a yellowed, solid lump instead of liquid. Routine checks and inventory logs stop old chemicals from piling up.

Fire-resistant cabinets or rooms play a daily role. Sprinklers, absorbent spill kits, and eye-wash stations offer last lines of defense. I’ve seen basic fire drills make the difference between a contained incident and a full-scale evacuation. No matter how experienced or cautious a team is, drills and written emergency plans save lives and keep insurance claims low.

OSHA and similar bodies insist on written protocols, but what keeps people safe boils down to experience and training. My time on a well-run floor showed that quick ID of chemical bottles, understanding PPE (personal protective equipment), and constant vigilance outperformed any manual alone. Regular refreshers, hands-on walkthroughs, and supervisor spot checks build a culture where cutting corners no longer appeals to anyone.

Investing in proper storage for 2-Butyne-1,4-diol demonstrates respect for everyone’s safety and the company’s bottom line. Lapses cost money, confidence, and sometimes health. It never hurts to ask for help, call the supplier, or revisit training. Practical habits beat wishful thinking every time chemicals land on the loading dock.

People rarely think about chemicals like 2-Butyne-1,4-diol unless they work in industries where contact becomes a possibility. This colorless, water-soluble liquid carries a formula that sounds more at home in a university lab than in daily life, but it actually shows up in commercial manufacturing. It acts as a building block for pharmaceuticals, synthetic fibers, and even some herbicides. Here’s where the trouble starts: hidden hazards often ride along with convenience. My own time in a chemical plant reminded me that familiar names on labels don’t mean they’re harmless.

Direct exposure to 2-Butyne-1,4-diol leads to skin, eye, and respiratory tract irritation. The European Chemicals Agency and the US National Institute for Occupational Safety and Health emphasize caution, listing symptoms like nausea and dizziness if inhaled. Skin contact can trigger burns; splash it in the eye and you risk permanent eye damage. Enough studies have shown that repeated or prolonged exposure has toxic effects on the kidneys and nervous system. Chronic toxicity stands out as a real concern. A 2021 industrial hygiene report linked acute nausea and headaches among warehouse workers to improper handling of this liquid. One can’t simply wipe off or ignore exposure; it demands real protection protocols.

Spills and leaks present serious problems well beyond factory gates. 2-Butyne-1,4-diol dissolves easily in water, and when it flows unchecked into rivers or groundwater, aquatic life pays the price. According to the US Environmental Protection Agency, acute exposure leads to decreased reproduction and even death in fish. While it doesn’t last long in the environment, quick breakdown often isn't quick enough to prevent immediate ecosystem damage. Clean-up crews face tough decisions about containment and removal. My own stint managing industrial waste for a mid-sized plant brought this challenge home—tracing run-off paths led straight to nearby wetlands.

Open bottles, leaky barrels, and shoddy personal protective gear create unnecessary risks. Workers deserve masks, gloves, and ventilation that meet safety standards. Training counts for more than posters hung in the break room. In plant safety walk-throughs, I learned many new hires got only a cursory mention of dangerous substances—never thorough education on what to do in case of a splash or spill. Regulations cover exposure limits, but enforcement often relies on company initiative and worker complaints. The Occupational Safety and Health Administration continues to urge companies to perform regular air monitoring and to store all chemicals properly.

Industries can substitute less harmful chemicals or use enclosed systems. Chemical engineers have developed “green chemistry” strategies to reduce reliance on toxic intermediates. Spill control plans, secondary containment, and scrubbers make unplanned releases less common. Community right-to-know laws let neighbors find out what chemicals move through local factories and warehouses. More transparency means fewer accidents and better emergency response.

Growing up near a chemical plant, I saw the divide between caution and carelessness. 2-Butyne-1,4-diol doesn’t often hit headlines, yet the risks run deep for both people and the planet. Every stake-holder—from employers to regulators to ordinary neighbors—plays a role in keeping exposure in check, one shift and shipment at a time.

| Names | |

| Preferred IUPAC name | But-2-yne-1,4-diol |

| Other names |

1,4-Butynediol

1,4-Butynylene glycol Butynediol But-2-yne-1,4-diol Vinylglycol |

| Pronunciation | /tuːˈbjuːtaɪn wʌn fɔː ˈdaɪɒl/ |

| Identifiers | |

| CAS Number | 110-65-6 |

| Beilstein Reference | Beilstein 1758736 |

| ChEBI | CHEBI:52668 |

| ChEMBL | CHEMBL15120 |

| ChemSpider | 14100 |

| DrugBank | DB02189 |

| ECHA InfoCard | 03ed0c52-ff30-4122-b522-bfc786051a21 |

| EC Number | 203-788-6 |

| Gmelin Reference | 82255 |

| KEGG | C01309 |

| MeSH | D016621 |

| PubChem CID | 7908 |

| RTECS number | EK2975000 |

| UNII | 7H7VCG8Y0M |

| UN number | UN2810 |

| CompTox Dashboard (EPA) | DTXSID3025272 |

| Properties | |

| Chemical formula | C4H6O2 |

| Molar mass | 90.10 g/mol |

| Appearance | White crystalline solid |

| Odor | Odorless |

| Density | 0.954 g/cm³ |

| Solubility in water | Soluble |

| log P | -1.18 |

| Vapor pressure | 0.011 mmHg (25 °C) |

| Acidity (pKa) | 13.7 |

| Basicity (pKb) | pKb = 9.4 |

| Magnetic susceptibility (χ) | -33.7·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.450 |

| Viscosity | 13 mPa·s (20 °C) |

| Dipole moment | 2.31 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 259.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −190.6 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -1205 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02, GHS05, GHS06 |

| Signal word | Danger |

| Hazard statements | H302, H312, H315, H319, H332, H335 |

| Precautionary statements | P210, P280, P302+P352, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 3-2-2 |

| Flash point | ~110°C |

| Autoignition temperature | 210 °C |

| Explosive limits | 1.2-10.8% |

| Lethal dose or concentration | LD50 oral rat 132 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 132 mg/kg |

| NIOSH | KN0510000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 2-Butyne-1,4-Diol: Not established |

| REL (Recommended) | 5 mg/m3 |

| IDLH (Immediate danger) | IDLH: 40 mg/m³ |

| Related compounds | |

| Related compounds |

1,4-Butanediol

2-Butyne 2-Butene-1,4-diol 1,4-Butyne diol diglycidyl ether |