1-Octanol first caught the attention of chemists well over a century ago, showing up as a byproduct during the study of natural fats and oils. Resourceful researchers during the industrial era sought out ways to better understand and separate long-chain alcohols from complex plant waxes. Slowly, the role of 1-Octanol became clearer as scientists began leveraging distillation and fractional crystallization to isolate this clear, faintly floral liquid. The material entered broader use once commercial interest grew mid-20th century, with fragrance and flavor specialists finding that 1-Octanol could add a strong, woody nuance. In those early days, I remember working on lab-scale distillations, measuring boiling points, and marveling at how this simple eight-carbon alcohol could solve some sticky separation problems and open up new products for the growing world of synthetic chemistry.

1-Octanol presents as a colorless, oily material with a mild, familiar scent—somewhere between fresh grass and waxed wood. Industries tap into it whether making perfumes, plasticizers, or intermediary chemicals. Unlike shorter-chain alcohols, 1-Octanol brings a distinct solvency and longer-lasting effect in fragrance blends, yet it holds onto the soft touch that keeps it valued over more volatile options. From my experience in workshop settings, the substance pours with a heavy, slick feel, never evaporating too quickly, always lingering on glass or metalware. Its versatility springs from its molecular structure, offering both hydrophobic and hydrophilic qualities, which chemists and manufacturers can fine-tune for their operations.

This compound sits at a boiling point of about 195 degrees Celsius. It’s practically insoluble in water, yet dissolves easily in organic solvents such as ethanol, ether, and chloroform. Its density (around 0.83 g/cm³ at room temperature) facilitates handling and blending, since it doesn’t separate quickly in common mixtures. Anyone who has worked with it in a lab notices its moderate refractive index and low volatility—factors that influence everything from handling protocols to reactor design. From a chemical standpoint, the hydroxyl group at one end of a carbon chain opens doors for reactions, but the long hydrocarbon tail ensures resistance against aggressive hydrolysis or oxidation under most conditions encountered in day-to-day production settings.

Manufacturers list 1-Octanol under the UN number 1993 as a “flammable liquid,” flagging its moderate fire risk. Purity levels matter deeply—technical grade sees at least 98% purity, while analytical grades clock in above 99%. Impurities show up as residual aldehydes and higher or lower alcohol homologues. Batch certificates come with precise gas chromatography breakdowns and moisture content. Safety labeling states GHS pictograms, flammability warnings, and proper storage guidance. Container labeling in warehouses always shows lot number, bottling date, hazard class, and suggested shelf life. During audits, I’ve seen inspectors double-checking these labels, emphasizing regulatory consistency and supply chain traceability, which keeps quality and safety at the forefront of warehouse practice.

Plants and synthetic labs arrive at 1-Octanol through different paths. On the natural side, workers harness coconut and palm kernel oils, running them through splitting, hydrogenation, and careful distillation. On the synthetic side, the Ziegler process often sets the tone: ethylene oligomerization forms 1-octene, which gets hydroformylated and hydrogenated to yield the alcohol. Both routes require strict temperature and pressure controls—plants deploy automated systems that constantly adjust flows and catalysts, keeping yields high and by-products minimal. In hands-on settings, the shift from bench scale to pilot plant production means keeping an eye on phase separations, ensuring reagent quality, and making sure those reactors don’t drift off spec, an effort that directly impacts downstream productivity.

The hydroxyl group at the end of 1-Octanol's chain welcomes esterification, etherification, and oxidation. In the fragrance industry, converting 1-Octanol to octyl acetate lends fruity notes to perfumes. Reacting with acids, such as acetic or formic, produces a range of esters used in both flavors and plasticizer synthesis. In lab-scale transformations, oxidation brings the product to octanal, which forms a base for many aroma chemicals. The material can undergo halogenation and conversion to ethers, though care must be taken to prevent overreaction and loss of yield. Over the years, I’ve learned that carefully controlling reagent ratios, temperatures, and reaction durations can mean the difference between a productive batch and wasted starting material.

Across chemical catalogs and shipping manifests, 1-Octanol appears as n-octanol, capryl alcohol, and octyl alcohol. It shares its listing with designations such as Alcohol C-8, 1-hydroxyoctane, and n-Octyl alcohol. Regulatory paperwork and industry databases often switch between these names, occasionally leading to confusion among those new to procurement or supply chain management. I recall reviewing incoming shipments labeled with varying synonyms and the importance of confirming CAS numbers (111-87-5 for 1-Octanol) to avoid any mix-up—especially as regulatory fines and production delays hang in the balance.

Gloves, goggles, and proper ventilation stay non-negotiable when working with large volumes of 1-Octanol. Spills bring both slip and fire hazards, so teams set up spill kits and maintain fire extinguishers within arm’s reach. Material safety data sheets lay out the need for grounded equipment to avoid static ignition. In the plant, the vapors demand explosion-proof ventilation and regular air monitoring. Workers receive training about skin absorption risks and how persistent exposure can cause dermatitis or minor CNS effects. Administrative controls, including restricted access areas and clear emergency protocols, keep daily operations safe. Seasoned operators learn to respect even “mild” chemicals since accidents stem from lapse of attention or shortcuts in storage and transfer practices.

1-Octanol finds regular use across perfumes, where its subtle floral, woody undertones smooth out sharp blends and act as fixatives for lighter notes. Paint and coatings manufacturers include it as a flow agent and surface active agent. In plastics, octyl phthalates made from 1-Octanol impart flexibility to PVC and other polymers. I’ve handled 1-Octanol in analytical labs as a calibration standard for gas chromatography, and watched as it acted as a lubricant in metalworking operations. Certain pharmaceutical formulations use 1-Octanol to improve solubility or as a permeation enhancer for topical drugs. Its penetration effect remains under close study for transdermal delivery, especially since the alcohol’s chain structure disrupts lipid layers. Agrochemical companies value it for insecticide delivery, thanks to its blend of solvency, volatility, and low toxicity compared to shorter-chain analogs.

Emerging research looks at 1-Octanol’s bioavailability and ability to permeate biological membranes, with focus on drug delivery and solvent properties. Teams investigate greener synthesis, searching for biodegradable catalysts and renewable feedstocks to lower the environmental impact. Efforts target using enzymatic processes for milder, selective alcohol production, producing less waste and hazards. I’ve seen collaborations between chemical engineers and pharmacologists outlining new uses in gene therapy solvent systems, while others push limits in optimized water treatment formulations, where octanol’s hydrophobic nature separates oil from water. Notably, analysts are enhancing detection protocols for octanol residues, aiding food and cosmetic safety compliance through rapid screening technology.

1-Octanol earns a moderate hazard rating, posing less threat than lower alcohols but still requiring controlled exposure. Acute oral toxicity in rodents falls in the several grams per kilogram range, signposting a wide usability margin. Systemic absorption remains low by skin contact, but repeated exposure can irritate skin and eyes. No solid links exist to chronic toxicity or carcinogenicity in standard study populations. Environmental assessments show slow degradation, prompting research into more rapid biodegradation pathways. The EPA and European regulators maintain close scrutiny on disposal practices, as aquatic organisms experience disruption above threshold concentrations. This data calls for stricter wastewater treatment and monitoring of production plant effluent to keep public water sources safe.

Synthetic methods for greener, high-purity 1-Octanol production appear ready for scale-up, promising lower costs and better sustainability metrics. This expansion could bolster its use across green chemistry, renewable plasticizers, and medical formulations requiring pharma-grade solvents. With continued regulatory focus on lowering workplace exposure, automated dosage systems, better personal protection, and improved monitoring equipment look set to improve safety. Ongoing interdisciplinary studies between pharmaceutical, materials science, and environmental experts bring fresh applications and new protocols. Businesses evaluating circular economy strategies see 1-Octanol’s versatility—spanning cosmetics, coatings, pharmaceuticals—as a foundation for next-generation product lines built around both performance and responsibility.

I’ve worked around labs and factories long enough to run into 1-octanol on a regular basis. At first glance, it looks like just another chemical with a name that doesn’t mean much unless you’re into organic chemistry. Once you dig in, its story gets pretty interesting, and the way it works through different industries shows how chemistry connects to daily life.

Chemical manufacturers count on 1-octanol as a building block. Companies use it to make plasticizers, which help soften plastics and make them flexible. Without those additives, many plastic products would crack or break too easily in the real world. I’ve seen that kind of detail matter whether it's toys, cables, or coatings on essential wires.

This alcohol also shows up in the making of surfactants and detergents. Ever cleaned a greasy kitchen counter? Products with chemicals like 1-octanol help break up the grime. It helps oils blend with water so that gunk finally rinses away. Surfactants made from this alcohol turn up in more household products than you might think—from shampoo to laundry soap to cleaners.

People often forget how much science goes into the food and fragrance industries. 1-Octanol has a distinct, oily smell with a touch of oranges and grass. That scent gets used in perfumes and as a flavoring agent. It’s not about dumping pure chemicals into food, but rather, adding tiny amounts to mimic or boost natural flavors, especially in fruit-inspired recipes. Regulatory bodies keep a close watch here—so there's confidence about safety in every application.

In the lab, 1-octanol shows versatility. Drug researchers use it to understand how medicines travel through the body. Measuring how a molecule dissolves between water and 1-octanol predicts if it might get through cell membranes. I’ve seen researchers decide which medicines to push forward based on those humble experiments.

It’s not just about theory, either. Some studies look at 1-octanol as a potential treatment for conditions such as movement disorders. There's curiosity about how it influences nerve signals—although it’s still a long road before doctors reach for it on the pharmacy shelf.

Handling 1-octanol safely stays important. It irritates skin and eyes if spilled, and the vapors can overwhelm in closed spaces. I learned early to respect chemical safety sheets and make smart choices with gloves and goggles. Safety culture protects workers and keeps the community around a plant out of harm’s way.

Sustainability can’t be ignored either. More producers look for sources like renewable crops to make alcohols, including 1-octanol. This model could cut down reliance on fossil fuels and shrink the environmental impact of chemical production. Some companies lean into that switch, while others face cost and technology challenges. I hope industry leaders keep moving in this direction.

1-Octanol plays many roles—softening plastics, improving cleaners, flavoring food, and supporting research. Most people never see the bottle, but its impact stretches into homes, hospitals, and manufacturing. Science makes these silent helpers part of everyday life, and with better stewardship, they can keep supporting innovation and safety for the next generation.

Browse through a material safety sheet for 1-octanol and the warnings don’t exactly leap off the page like some heavy-duty chemicals, but walking away convinced it’s completely harmless spells trouble. This clear, oily liquid has a faint odor and pops up everywhere from industrial processes to fragrances, and even as a flavoring ingredient. The question is, what should folks genuinely concerned about health risks expect?

Most people run into 1-octanol at work, in laboratories, or through finished consumer products. In the workplace, inhalation and skin contact usually come with the territory. At home, the risks remain much lower—unless someone’s actually handling concentrated 1-octanol or products that contain significant amounts.

The science is pretty clear about one thing: 1-octanol doesn’t belong on your skin or in your eyes. Direct contact tends to cause irritation, leading to redness or a burning sensation. If it winds up in the eyes, expect pain and watering. Breathing in the vapors doesn’t feel great either, sometimes causing headaches, dizziness, or even drowsiness if concentrations spike. Swallowing it brings on stomach pain and nausea. The bigger threat, though, comes from exposure over time at work or during manufacturing. Repeated or high exposure can dry out or crack skin, creating openings for other irritants to get in.

Human studies aren’t plentiful, but animal testing fills in some blanks about what 1-octanol does. According to the United States National Institute for Occupational Safety and Health (NIOSH), large amounts swallowed by animals caused nervous system depression—a fancy way of saying slowed reflexes and possible unconsciousness. The American Conference of Governmental Industrial Hygienists (ACGIH) groups 1-octanol with chemicals that cause mild irritation, but not with those known to bring on cancer, significant organ damage, or lasting harm with everyday levels found in industry.

Reading labels and understanding what’s in products used at work or home pays off. People deserve to know what could cause harm if something unexpected happens, or during routine use. Not every chemical that avoids the cancer or toxin lists deserves a free pass. I’ve seen first-hand in a lab how relaxed safety policies lead to carelessness and real injuries. Relying on safety data, understanding exposure routes, and training keeps risks manageable.

Gloves, goggles, and good ventilation should become the norm wherever 1-octanol shows up, especially in large batches. Clean up spills right away—skin doesn’t stand up well to repeated baths in this stuff. People should read the safety data sheet, not just skim it. If fumes build up, get fresh air right away. For companies, listening to workers who experience irritation or headaches in the lab means reviewing procedures and acting before bigger incidents happen.

Most cases of harm trace back to slips in training or not having the right safety gear on hand, not some hidden property of 1-octanol. Taking it seriously, even if it doesn’t have the scariest warning label, keeps workers and families out of unnecessary trouble.

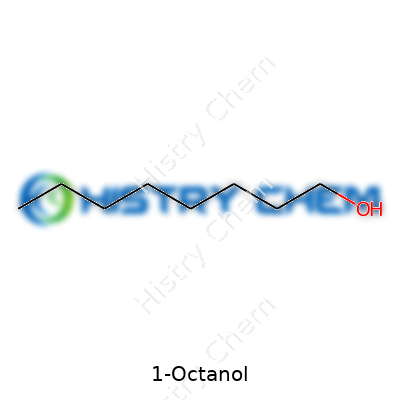

1-Octanol carries the formula C8H18O. This means it’s made up of eight carbon atoms, eighteen hydrogen atoms, and a single oxygen atom. That oxygen comes in as a hydroxyl group, turning a plain hydrocarbon chain into an alcohol. People often don’t give much thought to a string of atoms, but a basic formula like this unlocks a whole world for chemistry, industry, and everyday products.

I remember back in college labs, finding it funny that something so straightforward—a chain of carbons capped with an alcohol group—could have so many uses. Scientists use 1-Octanol as a standard for partition coefficients (log P values), which tells us how substances split between water and oil. Drug developers care about this data. It helps figure out how the human body handles medicines, which situations call for caution, and why some drugs work well and others don’t cross membranes easily.

1-Octanol isn’t just a tool for researchers, either. Here’s a fact: it appears in perfumes and flavors. A hint of this molecule shows up in the scent of oranges and the flavor of some whiskies. Its simple structure gives it a mild, earthy odor. That subtlety makes it useful in blending other ingredients without overpowering the more delicate notes.

Spilling 1-Octanol or handling it carelessly brings its own set of problems. Its chemical formula reflects a substance that doesn’t dissolve in water very well, which means it collects in soils and sediments. Over time, this can impact aquatic life since fish and small organisms mistake it for food or absorb it through their bodies. Taking safety seriously matters—skin contact and inhalation can both irritate, especially in poorly ventilated spaces or where people work with larger quantities. Industry and academia both have had to learn lessons on safety over and over, often the hard way.

Talking with colleagues who track pollution, they highlight the need for careful storage and quick cleanup to prevent lasting damage to water systems. Regulatory agencies focus on keeping levels low, guided by strict exposure limits. The hope is to avoid repeating past errors.

Working with 1-Octanol on the bench or the shop floor, gloves and proper ventilation matter far more than people think. A small spill evaporates quickly and spreads a strong smell, but larger releases need attention fast. Labs keep spill kits nearby, with absorbent pads and safety data sheets available for reference. These steps prevent costly mistakes.

Finding greener production methods has become a bigger focus. Some teams try using bacteria to produce 1-Octanol from renewable feedstocks instead of fossil fuels. This approach cuts down on environmental impact and brings science full circle: it’s a simple alcohol, but small improvements here ripple across chemical manufacturing and product safety.

In my work, knowing a formula like C8H18O opens the door to deeper questions. It forces teams to think about worker safety, environmental protection, and innovative science. The formula is just a starting line.

Anyone who's handled chemicals knows that good habits keep everyone safe. 1-Octanol, a fatty alcohol, plays a role in flavors, fragrances, and even as an intermediate in bigger chemical processes. Its storage might not seem like a big deal, but a single oversight can cause headaches—health risks, wasted product, lost money. Over the years working in labs, I've seen what happens when folks cut corners with chemicals like these. Spills, ruined inventory, and sometimes people getting sick. So every detail matters.

You'll find 1-Octanol as a colorless liquid with a mild, oily smell. It can irritate the skin and eyes, and breathing in its vapors isn't great for your lungs. It's also combustible—meaning a careless spark or hot light bulb close by could cause real trouble. Because it absorbs moisture and breaks down with strong acids or oxidizers, the wrong container or the wrong spot in storage could turn it hazardous fast.

Glass bottles or chemically-resistant plastic containers keep 1-Octanol safe from leaks and bad reactions. Tightly sealed lids make a big difference, not just for spill prevention, but also for keeping moisture out. Left exposed, it can pull water from the air, dilute itself, and lose its punch.

Cool, dry, and dark rooms slow down chemical breakdown. Heat speeds up reactions—and that means higher risk of pressure building up or the substance catching fire. Storing it away from sunlight and away from windows makes sense. Air conditioning or at least an area with good airflow helps, not only because it keeps temps down, but because vapors won’t linger around.

Flammable liquids need space, literally. Shelves or cabinets made of metal or flame-resistant materials separate the risky from the routine. Putting 1-Octanol on the same shelf as strong acids, peroxides, or oxidizers? That’s a big mistake. If it leaks, it could cause violent reactions, fires, or release toxic fumes.

Wearing the right gloves and goggles during transfer keeps accidents from turning into injuries. In my own lab days, colleagues would sometimes grab whatever gloves were closest. Here, choose nitrile or neoprene—they hold up well against alcohols. Fume hoods or at least well-ventilated spaces minimize the dangers from vapors. These steps aren’t just for the pros; everyone who touches the bottle should pick up the practice. Training should reach all levels, from the back room technician to the front office supervisor who might step in during busy days.

Spills call for absorbents that won’t react with alcohols. Clean-up kits belong nearby, clearly marked and stocked with all the right materials. Fire extinguishers rated for chemical fires should never be out of reach. Anyone storing 1-Octanol must know the emergency eyewash and shower locations and how to get help quickly—seconds matter in any chemical splash.

It never pays to treat chemical storage as an afterthought. Regulators set rules for a reason, but real safety often comes down to daily habits and a culture that expects people to speak up about risks. That mindset keeps teams safe, inventory intact, and reputations strong.

1-Octanol shows up across labs and industries. You see it as a colorless oily liquid, carrying a strong odor. It’s popular for making perfumes, plasticizers, and sometimes even pharmaceuticals. Working with it, you need your awareness tuned up, because this stuff can seriously irritate eyes and skin, and its vapors can get to your respiratory system.

One of the first things to keep in mind is how quickly chemical exposure can sneak up, especially through skin or eyes. I’ve seen experienced colleagues get careless, thinking a splash won’t hurt, only to end up with redness and discomfort for the rest of the day. That’s why wearing well-fitting safety glasses isn’t just for show. Regular lab coats and chemical-resistant gloves—nitrile or butyl—offer real, proven protection. Short sleeves or regular latex gloves simply don’t cut it for 1-Octanol.

Air quality in the work area makes a real difference. Running experiments with strong-smelling chemicals in a poorly ventilated room feels tough. Fume hoods exist for a reason, and I always gravitate toward one whenever 1-Octanol hits the bench. The vapors build up quickly, and a headache or coughing trap can develop even from a quick transfer if fans or air exchange aren’t adequate. People sometimes forget, but it pays to check those vent systems regularly.

I once saw a new technician drop a bottle just before lunchtime. Things got messy fast, with slippery floors and a powerful smell that drove everyone out. Clean-up means more than grabbing paper towels. Containing the spill with sodium bicarbonate or a commercial absorbent limits spread and controls fumes. Wearing splash goggles instead of regular glasses helps if there’s any splash-back during this kind of emergency. Don’t wait for others to notice; communicate fast with coworkers if a spill occurs and keep exit routes clear.

Knowing the procedure before you’re faced with a mistake saves panic. I’ve seen plenty of near-misses that got handled smoothly only because folks practiced drills and reviewed the material safety data sheet at the start. Keeping 1-Octanol bottles tightly sealed, marked, and stored in ventilated, locked cabinets far from sunlight or open flames stops fires and accidental exposure in their tracks. It’s simple, but cutting corners by keeping chemicals close to benches or near heat sources has caused more than a few close calls over the years.

Any leftover solution or contaminated gloves go into the dedicated hazardous waste. Pouring unused chemicals down the drain or tossing them casually with regular trash endangers not just the team but the wider community. Institutions keep protocols in place for good reason; they matter as much for our neighbors as for ourselves.

Chemical safety with 1-Octanol, like with any chemical, grows out of habits and respect—not just from rules posted on a wall. Whether you’re a seasoned chemist or a new technician learning the ropes, sticking to gloves, goggles, fume hoods, and smart storage saves more time and pain than carelessness ever could.

| Names | |

| Preferred IUPAC name | octan-1-ol |

| Other names |

Octan-1-ol

Capryl alcohol n-Octanol 1-Hydroxyoctane Octyl alcohol |

| Pronunciation | /ˈwʌn.ɒk.tə.nɒl/ |

| Identifiers | |

| CAS Number | 111-87-5 |

| Beilstein Reference | 1361076 |

| ChEBI | CHEBI:37841 |

| ChEMBL | CHEMBL14239 |

| ChemSpider | 7002 |

| DrugBank | DB03793 |

| ECHA InfoCard | EC 203-689-8 |

| EC Number | 203-918-6 |

| Gmelin Reference | Gm. 8297 |

| KEGG | C00790 |

| MeSH | D017361 |

| PubChem CID | 957 |

| RTECS number | RN8400000 |

| UNII | K7PZ2E2QD8 |

| UN number | UN3075 |

| Properties | |

| Chemical formula | C8H18O |

| Molar mass | 130.23 g/mol |

| Appearance | Colorless oily liquid |

| Odor | rose-orange; vegetable |

| Density | 0.824 g/cm³ |

| Solubility in water | 0.54 g/L (20 °C) |

| log P | 3.0 |

| Vapor pressure | 0.133 mmHg (at 25 °C) |

| Acidity (pKa) | 16 |

| Basicity (pKb) | 15.5 |

| Magnetic susceptibility (χ) | -64.0e-6 cm³/mol |

| Refractive index (nD) | 1.429 |

| Viscosity | 7.364 mPa·s (25 °C) |

| Dipole moment | 2.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 296.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -322.4 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –5120.7 kJ/mol |

| Pharmacology | |

| ATC code | V03AB44 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | Precautionary statements: P210, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0-健康1-易燃性1-反応性0 |

| Flash point | Flash point: 81 °C |

| Autoignition temperature | 410 °C |

| Explosive limits | Explosive limits: 1.1–9.2% |

| Lethal dose or concentration | LD50 oral rat 3200 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral-rat LD50: 4,300 mg/kg |

| NIOSH | NA0165 |

| REL (Recommended) | 50 ppm |

| IDLH (Immediate danger) | 750 ppm |

| Related compounds | |

| Related compounds |

1-Hexanol

1-Heptanol 1-Nonanol 1-Decanol Octane Octanal Octanoic acid |