Back in the early days of synthetic organic chemistry, few researchers worked without getting their hands dirty in dense, volatile substances. The story of 1,5-Dibromopentane starts in that hands-on era, where German and English chemists scoured natural oils and coal for molecules that could move industrial synthesis forward. Through the mid-twentieth century, labs found that swapping out hydrogens for bromines along a carbon backbone opened doors to new plasticizers, pharmaceuticals, and intermediates. Decades of refinements made large-scale production routine. Many scientists still recall graduate courses that traced halogenated chains through their reaction maps, sending generations to the flask to test yields and byproducts. The substance remains a staple not by nostalgia, but because it delivers reliability in reactivity and downstream versatility.

The compound itself may sound exotic, but it’s just an unassuming liquid at room temperature—no glamour, just consistency. 1,5-Dibromopentane walks a middle ground between reactivity and stability, so it can sit on a shelf for months without fuss, then react cleanly when it meets a nucleophile. Users value these qualities when searching for building blocks that won't surprise them halfway through a synthesis. With both ends capped by bromines, the molecule links carbon chains efficiently and repeatedly, serving as a perfect tool for modifying backbone structures or building cyclic systems. Its presence in catalogues underlines this utility: researchers reach for it not because it’s rare, but because it’s dependable.

In practical settings, clarity and purity matter. 1,5-Dibromopentane appears as a clear, colorless to pale yellow liquid, with a mild but distinctive odor that signals its weight as a halogenated compound. Its boiling point hovers around 242-243°C, and melting comes at roughly the -15°C mark. The density, close to 1.6 g/cm³, calls for care in handling, as heavier liquids demand thoughtful storage and transport to avoid spills and leaks. It remains only slightly soluble in water but mixes well with most organic solvents—an advantage for blending into common laboratory solutions. Chemists rely on the molecule’s steady vapor pressure and reasonable refractive index (about 1.505) to spot-check purity and chart yield in synthesis. None of these numbers are trivial; each detail speaks to the experience of handling and scaling this compound in real industry settings.

Product labels don’t just tick regulatory boxes; clear details on purity, batch information, and handling let researchers cross-check chemicals against process requirements. High-grade 1,5-Dibromopentane generally ships at 98% purity or higher, often accompanied by GC or NMR reports for reassurance. The container—glass or lined metal—bears UN shipping numbers, hazard pictograms, and a suite of safety instructions. CAS Registry Number 111-24-0 marks the product unambiguously in global inventories. Shelf life remains stable under dry, oxygen-free conditions. These technical notes may seem routine, but good documentation spares endless headaches in quality control and regulatory audits.

Old recipes stick for a reason, and 1,5-Dibromopentane comes from a classic method: direct bromination. Starting with 1,5-pentanediol or n-pentane, chemists dose in bromine under controlled light or heat to drive the reaction toward terminal substitution. Aqueous or organic solvents keep the reaction uniform, while radical initiators or iron salts guide efficiency. Skilled operators watch temperature and mixing rates to keep side-products at bay. After reaction completion, extraction and distillation polish the product, limiting contamination by mono-brominated or overbrominated chains. Combine hands-on experience in scale-up with modern analytical checks, and the outcome stands up to scrutiny across multiple industries.

Synthetic chemists lean on 1,5-Dibromopentane to knit together complex structures. Each bromine atom gets replaced by a wide menu of nucleophiles, from ammonia and primary amines to sulfur-, oxygen-, or nitrogen-based reagents. This flexibility transforms the substance into a stepping stone for polymers, cyclic ethers, and pharmaceuticals. In research, the molecule often forms crowns and heterocycles, with its five-carbon span setting the ring size just right for various macrocycles. Reductions, coupled substitutions, and even Grignard-type additions open more functional doors. With every reaction, skill counts—controlling temperature, timing, and reagent mix can swing outcomes from mess to milestone.

Catalog searches turn up many aliases for this single compound: Pentamethylene dibromide fills some shelves, while others list 1,5-pentanediyl dibromide, or even simply dibromopentane. Each moniker links back to the same core structure: a five-carbon alkane chain capped by two bromine atoms. Users should always double-check CAS numbers or draw structures by hand to avoid mix-ups with closely named cousins—accuracy prevents wasted resources and confusion in procurement cycles.

No one should gloss over the safety profile. Like most organobromine compounds, 1,5-Dibromopentane deserves careful respect. Contact with skin or inhalation can trigger irritation, and long-term exposure needs tight controls. Proper use of chemical fume hoods, gloves, lab coats, and eye protection stands as non-negotiable. Storage in cool, dry places, away from strong bases and oxidizers, keeps risks low. Labels must alert users to toxicity, environmental hazard, and flammability, aligning with GHS regulatory requirements. Industrial settings layer on ventilation, spill response plans, and regular safety audits. Training saves more than worry; it cuts real risk to teams and communities.

Real-world uses reach far beyond academic shops. In pharmaceutical labs, 1,5-Dibromopentane serves as a scaffold for linking biologically active fragments—a first step toward new antibiotics or antivirals. Polymer scientists count on it to set chain lengths or drive crosslinking in specialty materials, including membranes and ion-exchange resins. Fine chemical manufacturers value its crisp reactivity in process intensification, where speed and yield define commercial success. Environmental chemists sometimes tag the molecule in tracer studies, tracking pollutant breakdown or movement through soils and water. Each field raises fresh questions about efficiency, process safety, and sustainability.

New directions emerge constantly in chemical R&D. Teams push the reactivity of 1,5-Dibromopentane toward greener, more selective transformations—reducing waste, cutting hazardous byproducts, or expanding the reach of mild conditions. Catalysis emerges as a major theme, with metal and organocatalysts unlocking new coupling or selective activation routes. Biochemists examine how structural tweaks could bridge disciplines, such as linking synthetic chains with enzymes or proteins. Each published study or patent underscores the broader strategy in research: make reliable molecules work smarter, not harder, by blending classic know-how with modern science. My own time in multidisciplinary teams taught me the worth of this approach, seeing failed reactions lead to creative pivots that ultimately improved yields or cut waste disposal costs.

There’s no escape from toxicology if you care about health and the environment. 1,5-Dibromopentane, like most dibrominated alkanes, poses moderate hazards in acute and chronic scenarios. Studies in rodents point to central nervous system effects at high doses; in aquatic systems, bioaccumulation raises red flags for long-term impact on fish and microorganisms. Regulations worldwide require detailed assessments before new uses or scale-ups. Laboratories track workplace air concentrations, and biological monitoring of exposures forms part of safety culture. Ongoing research seeks to understand subtle metabolic effects, breakdown products, and remediation strategies. The next generation of chemists builds checks into every project phase—lab, pilot, and plant—putting health and transparency front and center.

Science marches forward, and so do expectations for safer, more sustainable chemistry. For 1,5-Dibromopentane, the next chapters likely focus on cleaner production pathways, leapfrog technologies that swap bromine sources for less hazardous options, and green solvent systems that minimize emissions. Demand for specialty polymers and pharmaceutical intermediates won’t disappear, but every link in the supply chain faces pressure to adopt low-impact handling and disposal. In my work, the shift toward automation and digital process monitoring already promises tighter controls, sharper analytics, and lower environmental footprints. Collaboration between academia, industry, and regulators will shape the rules and rewards for the next era—turning a time-tested compound into part of a smarter, safer chemical toolbox.

Sometimes we come across a chemical like 1,5-dibromopentane and it barely gets a second look. Down the production line, though, this chunky five-carbon chain with bromine atoms on both ends plays a big role. It's handy for folks in labs who want to connect things together, especially in the world of organic chemistry. The two bromine atoms act like handles. Chemists grab these handles to build bigger, more complicated molecules—stretches of carbon and hydrogen, stitched together for a purpose. I remember my time in the lab cheering when a reaction actually gave a clean, straightforward product using this building-block approach.

1,5-Dibromopentane goes into making drugs, coatings, and fancy plastics. When manufacturers want to create molecules that need a five-carbon spacer—something not too short and not too long—they often reach for this compound. It helps piece together two parts of a molecule that shouldn't sit too close. In pharmaceuticals, this spacer trick builds drugs with precise shapes so they line up just right inside the body. Accurate distances can mean the difference between a treatment working, or not.

Getting down to basics, those bromine atoms jump into reaction after reaction, bumping off and inviting new groups. Chemists make use of this reactivity to add variety. This means new flavors in fragrance chemistry, tough new polymers for electronics, or fresh dyes that cling better to fabric. All of these uses trace back to that double-ended tool—bromopentane. It’s the sort of thing most never see, though it shows up everywhere from car interiors to contact lenses. Not glamorous, but necessary.

Stories from industry remind me why safety comes first. 1,5-Dibromopentane, like a lot of its halogenated cousins, doesn’t belong outside a fume hood without precautions. Exposure can irritate eyes, skin, and maybe more if inhaled. Some folks overlook these risks. They shouldn’t. Having gloves, goggles, and ventilation close by isn’t overkill. Regulations keep shifting as we learn more, and factory standards improve with better information. People oversee these changes because accidents catch up fast.

Another worry comes up after the reactions finish. Halogenated waste like this doesn’t just disappear. Dumping leads to lasting problems in water and soil. Proven solutions come down to tighter controls and waste treatment before discharge. Activists and scientists keep pressing for stronger oversight. In my own experience, pushing for better disposal never goes out of style. Factories can capture and neutralize these chemicals before they escape into local streams. Smart design means less waste from the start.

As green chemistry grows, more people ask about the future of chemicals like 1,5-dibromopentane. Can we substitute cleaner alternatives? In some reactions, yes. Some companies invest in less hazardous spacers, but old habits persist until costs drop. Good science depends on reliable supply, safe use, and frank discussion about environmental burdens. Progress shows up slowly, through safer labs and tighter rules. Having spent hours in the lab, I watch for new breakthroughs. Change begins with small steps, often with unsung molecules that quietly make connections.

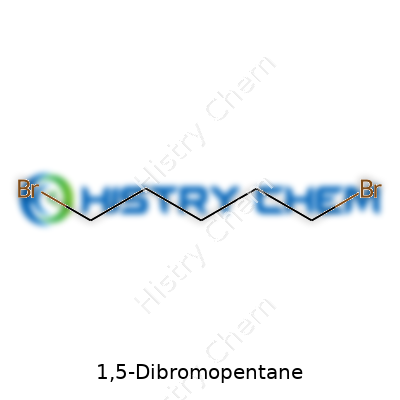

Most of us spend little time considering what chemicals make up everyday life unless we're mixing up a new recipe or coming across a strange label at work. In reality, the foundation of both medicine and materials science rides on understanding these building blocks. Take 1,5-Dibromopentane as an example: it’s not a household name, but knowing its molecular formula—C5H10Br2—cracks open a whole world of chemical reactions, industry uses, and even safety alerts.

C5 tells you the backbone has five carbons. H10 shows it’s saturated, which means every carbon atom holds as many hydrogens as possible, except for two spots. Those spots? That’s where the bromine atoms, Br2, attach—one on each end of the chain. If you picture this, it’s a straight-carbon chain, five units long, bookended by bromine atoms.

Why get so precise about the formula? Chemical formulas are more than just trivia. A tiny shift—a carbon gone missing, one less hydrogen, a chlorine traded for a bromine—can turn a safe additive into something with dangerous side-effects or completely change how a substance acts. C5H10Br2 ensures researchers can build, modify, and analyze new compounds with confidence.

Folks using 1,5-Dibromopentane aren’t just staring at numbers. Take the lab technician putting together a new flame retardant mix, the drug researcher synthesizing a potential medicine, or even those trying to break down pollutants hanging around in water or soil. They all need clear, trusted data. Gloves and goggles only take you so far—if you misread the building blocks, mistakes slip through. Extra bromines on the chain can make a difference not just in safety, but in legal limits and product performance.

Years of repeated incidents—spills, workplace burns, eco-issues—prove the case. Getting the molecular formula right narrows risk, helps companies meet environmental standards, and lets regulators set enforceable rules. Good formulas mean less accidental poisoning, better recycling plans, and safer air in the plant down the road.

You can’t just rely on scribbled notes or word of mouth. Textbooks still serve as a solid reference, and so do peer-reviewed scientific databases like PubChem and Reaxys. Manufacturers often supply a Certificate of Analysis for each batch, and those details should always be double-checked before any large-scale operation. Changing regulations or supplier info can trip up even seasoned chemists. Training staff to read and understand chemical data before handling new compounds pays off fast, saving trouble before it starts.

Most folks don’t toss around organobromines at home, but anyone with a stake in manufacturing, research, or regulations relies on solid science—the kind that starts with the correct molecular formula. Sharing knowledge across teams and investing in chemical literacy could prevent the next costly mistake. It doesn’t hurt to stay curious, either; chemistry, like life, rewards those who pay attention to what’s hidden beneath the surface.

Chemicals such as 1,5-dibromopentane rarely show up in everyday conversations, but for folks in labs, manufacturing, and environmental health, they’re pretty familiar. It’s a clear, dense liquid with a sharp smell, used in organic chemistry to link carbon chains together or to make plastics and pharmaceuticals. On the surface, it might seem like any other industrial chemical, but lurking beneath that is a real concern about its effects on health and the environment.

Coming into contact with 1,5-dibromopentane happens mostly in workplaces. From my own years working in research, gloves and proper ventilation were a must any time brominated chemicals came out. There’s a reason for that. Data from the European Chemicals Agency points out that this compound can cause skin and eye irritation. Breathing in the vapors means risking coughs and sore throats. Many safety datasheets warn against long unprotected exposure; the stuff can penetrate skin and get into your system. Over time, that spells trouble for nervous systems and organs like the liver and kidneys.

What makes these risks important? Unlike household cleaners you can buy at the grocery store, people can’t just toss this stuff out or rinse it down the drain. It doesn’t break down easily. Brominated compounds tend to hang around in the environment, and some can build up in fish and wildlife. The result can be long-term pollution in water and soil. In a world where every community is downstream from somewhere else, those persistent pollutants eventually touch all of us.

Studies and regulatory reports show that 1,5-dibromopentane has moderate toxicity compared to other brominated organics, but its risks aren’t just guesswork. The American Conference of Governmental Industrial Hygienists and similar agencies study workplace exposure limits. Their findings consistently tell us that without strong protective measures, workers might suffer headaches, dizziness, and allergic reactions. In larger spills, or if handled carelessly, this chemical could trigger nausea or damage internal organs over time.

Workers need more than warnings—they need strong systems to keep them safe. Strict ventilation, reliable gloves, goggles, and dedicated chemical disposal routines can lower risks dramatically. I remember labs where spill kits and emergency showers stood ready every day. That wasn’t paranoia, but respect for these real dangers. Regular reminders and good training became a line of defense stronger than any single piece of equipment.

Companies can no longer just focus on immediate profits. There’s real power in demanding better labeling, transparency about what chemicals are in use, and community right-to-know laws. Those efforts build public trust and keep neighborhoods safe. Instead of treating environmental rules as a burden, savvy managers see them as smart investments—less liability, better reputations, and healthier workers.

In my experience, genuine safety requires attention to detail and a willingness to speak up when something seems off. Regulators, employers, and everyday workers each play a role. If proper safety standards are enforced, accidental or careless exposure falls. If oversight is weak, the hidden hazards of 1,5-dibromopentane create health problems years down the line. Doing the right thing takes effort, but in a world overflowing with chemicals, it’s the only responsible way forward.

Anyone who’s worked around chemicals understands that proper storage isn’t just bureaucracy—it keeps people safe and protects the environment. 1,5-Dibromopentane sits among those substances that seem stable on paper, but real-world labs and warehouses have seen how things go sideways when folks cut corners.

I’ve spent years on factory floors and in teaching labs. At every stop, storing 1,5-Dibromopentane has meant keeping respect for its properties front and center. It’s a colorless liquid, smells harsh, and does a number on your skin and lungs if you get careless. Leaks or spills can trigger headaches or worse. Nobody wants that on their conscience—or safety report.

At our facility, chemical storage brings together knowledge, vigilance, and good habits. For 1,5-Dibromopentane, we use tightly sealed containers made from glass or specialized plastics that stand up to halogenated hydrocarbons. You won’t see it kept in metal drums because it reacts and breaks down certain metals over time. That choice alone cuts down on contamination and danger over the long haul.

Temperature makes a big difference. We park containers in a well-ventilated room, away from direct sunlight and heat sources. Heating doesn’t just risk faster evaporation—it can trigger decomposition or cause pressure to build up inside containers. Cases I’ve seen of bulging barrels come from folks forgetting this step.

One of my worst early lab experiences came from someone leaving a bottle too close to a window. A hot afternoon sun pushed pressure up, and the next morning, the bottle’s seal let loose. Not a disaster, but enough fumes rushed out to remind our whole department: don’t mess with safe temperature zones.

Storing chemicals teaches you to think about what’s sitting nearby. 1,5-Dibromopentane shouldn’t share space with strong oxidizers, alkalis, or acids. Accidental mixing kicks off dangerous reactions, and those reactions rarely wait for you to suit up. On our shelves, we keep a safe buffer between incompatible chemicals. Printed hazard labels, clear dividers, and an updated inventory make it less likely for someone to grab two substances that shouldn’t mix.

Regular checks matter more than high-tech alerts. Weekly walk-throughs, where techs look at containers for cracks, bulges, or leaks, catch issues software can’t spot. It pays off all year. You’ll find small problems before they become stories in safety meetings.

Everyone talks about PPE and spill kits, but routines shape safe storage more than equipment alone. At our place, staff practice drills, review the material safety data sheet, and know how to clean a spill quickly. We keep the right absorbent materials within arm’s reach.

Good storage shouldn’t feel like a chore—it should be second nature. Training new hires so they know the “why” behind every rule turns nervous beginners into safety leaders. Teams stay alert, and nobody treats warnings as background noise.

Chemical management can sound dry on paper. In practice, it protects real people. 1,5-Dibromopentane will behave as long as those working with it keep up the right habits. From container choice to regular checks, every detail gives peace of mind and lets the work flow without worry.

I’ve handled my fair share of organic chemicals in the lab, and 1,5-dibromopentane never fails to remind me of the messes it can make. This compound, with the formula C5H10Br2, shows up as a colorless to pale yellow liquid. Hold the bottle up to the light and you see right through it, unlike thicker or more opaque halides. Spill a few drops: things get oily—slippery, tenacious, almost impossible to clean up with water alone. That slick feel comes straight from its molecular structure, giving chemists headaches and making it easy to tell if someone’s been less than careful at the bench.

Your nose picks up a sharp, somewhat sweet or chloroform-like smell. That lines up with a boiling point around 221–223°C — not low enough to make it vanish in open air, but enough to suggest some evaporation in a warm room. It doesn’t float away as quickly as some smaller alkyl halides. Every time I open a fresh bottle, I get that chemical aroma, sharpening my focus and reminding me to crack a window and double-check the gloves. That persistent smell tells you not to leave anything uncapped on the bench—its moderate vapor pressure makes that risky.

Pour it out and it settles under water. The density sits at about 1.535–1.540 g/cm3 at 20°C, which means it’s close to one and a half times as heavy as water. This property makes phase separation easy in extractions. During syntheses, I can pull off a lower layer with confidence, knowing nothing will sneak up above the water line.

Solubility sits low in water—so low you’d miss it if you blink—clocking in at less than 1 gram per 100 milliliters. It floats best in the company of nonpolar solvents like ether, benzene, or chloroform. That makes it handy in organic syntheses, yet also means a spill stays around in cracks and crevices for ages. Good gloves and tight seals go a long way; this stuff clings tenaciously to surfaces, and traditional soaps don’t break it up easily.

A melting point below -20°C tells me I never have to worry about this compound freezing in a typical storage space. It stays a mobile liquid for almost any working condition I’ve run across. Those boiling numbers—just above 220°C—make it manageable for distillation and careful purification, provided someone watches the heat and avoids inhaling escaping fumes. Accidents can mean headaches and, for sensitive people, dizziness or irritation.

Every bottle reminds me there’s more to chemistry than textbook numbers. One slip with 1,5-dibromopentane on glassware leaves a tell-tale oily smear that water alone can’t conquer. In scale-ups, weighing out this dense, slow-flowing liquid teaches patience and respect. Handling halides like this, with their persistence and strong odors, shaped my habits: fresh gloves, proper ventilation, and a bottle of solvent close at hand. Every lab worker should learn these lessons early to avoid the lingering mess that an underappreciated dibromopentane can leave behind.

Lab safety starts with knowing the character of what you work with. 1,5-dibromopentane looks harmless in the bottle, but its physical traits demand respect. Better bottle designs, clearer hazard labeling, and stronger personal protective equipment mean accidents and exposures can stay rare. Building good habits isn’t just about ticking boxes; it’s about respecting these oily, persistent, nose-tingling fluids that shape our daily routines in the lab.

| Names | |

| Preferred IUPAC name | 1,5-dibromopentane |

| Other names |

Pentamethylene dibromide

Pentane-1,5-diyl dibromide |

| Pronunciation | /ˈwʌn.faɪv daɪˈbroʊmoʊˈpɛnˌteɪn/ |

| Identifiers | |

| CAS Number | 111-24-0 |

| Beilstein Reference | 1640059 |

| ChEBI | CHEBI:141715 |

| ChEMBL | CHEMBL15868 |

| ChemSpider | 12044 |

| DrugBank | DB02197 |

| ECHA InfoCard | 03d290b1-8cbe-441e-93b1-d0b76c41a543 |

| EC Number | 208-906-3 |

| Gmelin Reference | 84897 |

| KEGG | C01785 |

| MeSH | D017209 |

| PubChem CID | 11108 |

| RTECS number | RP8750000 |

| UNII | MJ3Q14M9S8 |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | DTXSID9020602 |

| Properties | |

| Chemical formula | C5H10Br2 |

| Molar mass | 215.95 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | sweet |

| Density | 1.595 g/mL |

| Solubility in water | Insoluble |

| log P | 2.78 |

| Vapor pressure | 0.07 mmHg (20°C) |

| Acidity (pKa) | 14.4 |

| Magnetic susceptibility (χ) | -8.57 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4990 |

| Viscosity | 2.08 mPa·s (20 °C) |

| Dipole moment | 1.6 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 309.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -44.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3733.1 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 96 °C |

| Lethal dose or concentration | LD50 oral rat 5750 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3,350 mg/kg (rat, oral) |

| NIOSH | RX8575000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 ppm |

| Related compounds | |

| Related compounds |

1,5-Dichloropentane

1,5-Diiodopentane 1,5-Difluoropentane 1,5-Dibromohexane 1,4-Dibromobutane |