As industries sought new monomers for advanced adhesives, coatings, and resins, 1,10-Decanediol Diacrylate entered the scene. Chemists first aimed to bridge gaps in performance seen with earlier acrylates, especially in improving flexibility and resistance to wear. Research records from the late twentieth century show push from both academic and commercial labs searching for aliphatic diols offering longer chain backbones. The desire for enhanced weatherability and low shrinkage led pioneers to decanediol-based solutions. A few decades ago, standard polyester acrylates often turned brittle under stress; chemists tuning molecular length with 1,10-decanediol brought a more robust material for UV-curable technology. So as UV curing became mainstream, this diacrylate carved out its place for anyone who needed both toughness and clarity.

Each batch of 1,10-Decanediol Diacrylate answers a call for high-purity monomers in advanced material applications. People see this compound as a clear or slightly yellowish viscous liquid that packs two acrylate groups at either end of a ten-carbon aliphatic chain. This structure pulls double duty—bringing flexibility and offering enough reactivity for fast crosslinking. Manufacturers rely on this balance to deliver products that stay intact where cheaper acrylates fall short, especially in UV- and electron beam-cured systems. Those seeking lower odor and improved hydrolytic stability find this diacrylate stands out in a crowded field, tracing a direct line from feedstock purity through every step of production.

The physical makeup of 1,10-Decanediol Diacrylate tells you plenty about its behavior. With a molecular formula of C16H26O4 and a molecular weight of about 282.4 g/mol, this diacrylate comes off as a moderately viscous liquid at room temperature. It smells faintly characteristic, never overpowering. Its boiling point reaches above 250°C, while flashpoint usually breaches 120°C, signaling enough safety margin during handling. The density hovers around 1.01 g/cm³, and its solubility in water sits low, allowing strong phase separation in emulsions but good miscibility in various organic solvents. Double bonds at each acrylate site make free radical polymerization both efficient and controllable, letting formulators try new chemistries without retooling every step.

Quality counts when suppliers fill orders for this compound. Buyers expect purity levels above 98%, with low acid and color values—commonly reporting an acid number below 1 mg KOH/g and Gardner color under 2. Inhibitors like MEHQ or BHT often pop up on the certificate of analysis, protecting the acrylate groups during storage and transit. Labels list the recommended storage temperature, usually below 30°C, and stress the need for ventilation because unintentional heat speeds up unwanted polymerization. Packaging follows strict standards: dark HDPE drums and nitrogen blanketing help keep air and moisture out. Documentation always includes hazard statements and REACH compliance. Every detail on paper translates to easier compliance and less stress on the production floor.

The synthesis of 1,10-Decanediol Diacrylate starts from decanediol, which comes from reduction of the corresponding ester or acid. The diol reacts with acrylic acid or its derivatives under acidic catalysis—commonly sulfuric acid, sometimes with a Dean-Stark trap to pull water from the esterification step. Excess acrylic acid gets washed out and the final product undergoes vacuum stripping to remove residual monomers and byproducts. Purification cycles often use adsorption columns to keep color and impurities low. The process only works if temperature and mixing stay tightly controlled, since runaway reactions waste material and endanger workers. I’ve seen operators monitor every gauge on the line, because any spike could threaten a costly batch and force an extended shutdown for cleaning.

Polymer chemists make the most of this diacrylate’s twin acrylate groups. The monomer undergoes free-radical polymerization with photoinitiators, forming tough networks in UV-curable paints, inks, and adhesives. Formulators often blend it with other acrylates to adjust viscosity or crosslink density, depending on final performance targets. Copolymerization with hydroxy-functional acrylates or methacrylates tunes mechanical strength, impact resistance, or flexibility. Cosolvent blends sometimes improve substrate adhesion or wetting. Some researchers explore functionalization of the diol backbone itself, seeking enhanced flame resistance through halogenation, or adding siloxane arms for anti-fog applications. Each variant opens new application territory, though basic free-radical addition remains the workhorse for most commercial lines.

This compound answers to a few other names across technical documents. You might catch it labeled as Decanediol diacrylate, 1,10-Diacryloyldecane, or DA-10. Some distributors use trade names like "Acrylate DDA-10" or list it by its CAS number, 36841-68-6, to sidestep confusion in purchasing. In daily work, abbreviations help keep things efficient during communications between R&D and manufacturing. Anyone reading a safety data sheet or material inventory log picks up these synonyms without missing a beat; the goal is always clarity, because a misread label means wasted time and possible risk.

Workplace safety draws sharp lines around acrylate monomers. Direct contact risks skin irritation, respiratory issues if vapors get concentrated, or even sensitization over repeated exposure. PPE rules call for nitrile gloves, chemical splash goggles, and lab coats. Good practice means using local exhaust ventilation near filling stations or mixing tanks. Storage rooms must stay cool, dry, and low in light, protected against direct sun or strong oxidizers. Fire departments and insurance carriers both demand clear signage and access to spill kits containing neutralizing agents and inert absorbents. Training goes beyond the basics—teams drill for accidental polymerization incidents and monitor for leaks using periodic VOC meters. In my visits to factories, line workers never hesitate to double-check a seal or purge a line, because one oversight can mean a long scrub-down or insurance claim.

End users pull 1,10-Decanediol Diacrylate into a surprising variety of products. UV and EB curable coatings on flooring or electronics call for this diacrylate to balance hardness and durability with flexibility. Ink formulators value it in high-gloss, fast-cure flexographic and digital printing systems. Specialty adhesives benefit from its longer chain backbone, delivering both strong initial tack and finished resilience, which stand up to thermal cycling or vibration. Medical device coatings—catheters or stents—gain low extractables and chemical resistance, critical in sensitive environments. Optical applications, like lens adhesives and protective films, rely on its transparency and lower yellowing tendency under sunlight. Field engineers and lab staff often share stories of pushing a formulation beyond the lab, only to appreciate the consistent cure profile and lasting clarity after months of product use.

Academic labs and private labs keep chasing better, greener processes to make this monomer with less waste and energy. Teams have switched from traditional acid catalysts to enzyme-based methods, cutting byproducts and making purification easier. Some explore bio-based feedstock routes—using plant-derived diols—to lower dependence on petroleum inputs, eyeing certifications for renewable content. Upstream research focuses on customizing the acrylate groups or attaching them at different points of the backbone, aiming for fine-tuned properties. Downstream, R&D blends this diacrylate with nano-fillers or design resin mixtures for specialty electronics, seeking anti-static surfaces or tailored refractive indices. Funding often comes from government or industry consortia looking to build out resilient supply chains and greener chemistries without sacrificing product reliability or worker safety.

Toxicologists keep a close eye on acrylate monomers, knowing small changes in structure can mean big shifts in health impact. For 1,10-Decanediol Diacrylate, acute toxicity registers low in standard animal models, with limited systemic effects by oral, dermal, or inhalation routes at small doses. Still, repeated or high exposures produce contact skin sensitization, a real problem for both workers and end users. Chronic studies check for mutagenicity and carcinogenicity, while in-vitro screening evaluates endocrine disruption or aquatic toxicity. Industry data sets often include dose-response curves and environmental fate data to keep regulatory filings up to date. I’ve seen procurement teams request new safety data before swapping suppliers, since a slip-up here might close off a customer account or cause trouble in product registration.

Moving forward, 1,10-Decanediol Diacrylate will see growing demand in emerging markets for rapid-cure, high-performance materials. Additive manufacturing and smart coatings open large new channels, especially as electronics and biomedicine seek custom-engineered substrates. The push for more sustainable chemistry means future production could lean into biocatalytic synthesis and green solvents. Applications in 3D printed electronics and flexible devices promise large volumes as the monomer’s flexible backbone blends toughness with processability. Regulation will press for safer alternatives and better data sharing, but technical gains in synthesis, formulation, and toxicity reduction suggest this compound will keep its seat at the table. Anyone managing a supply chain or developing functional materials will keep an eye on its price, availability, and regulatory standing, knowing an edge here translates directly into product success or failure in competitive markets.

Step into a workshop full of raw chemicals and 1,10-Decanediol Diacrylate might look pretty unremarkable. Dig a little deeper, though, and it reveals its true value. Chemists rely on this compound to build materials that demand toughness and stability. Its molecules connect long chains in resins and plastics, locking everything together. So, it isn’t just a chemical in a bottle—it’s a backbone in products that stand up to friction, heat, and daily wear.

Ever drop a smartphone and wonder why screens resist shattering these days? Materials like 1,10-Decanediol Diacrylate help chemists create resins and adhesives that can handle knocks and scrapes. These acrylic resins harden quickly under UV light, which matters in processes like 3D printing, dental fillings, and finishing wood surfaces. Tooth fillings and scaffolds for bone repairs use acrylic resins based on similar chemistry; they have to last inside the body and not break down under stress or heat.

Cabinetmakers and car painters want coatings that don’t bubble or peel when the weather changes. 1,10-Decanediol Diacrylate finds its way into high-end paints and varnishes, making surfaces slick, glossy, and tough as old boots. As a formulator, I’ve seen firsthand how a bit of this diacrylate transforms a water-thin resin into a shell that shrugs off cleaning chemicals. Even concrete floor coatings benefit, as this helps prevent cracks and stains from taking root. Homeowners and factory workers both get longer-lasting surfaces, which saves money and cuts down on waste.

Factory lines phone up suppliers for 1,10-Decanediol Diacrylate when making circuit boards and touchscreens. These industries demand clean, stable polymers that won’t yellow or sag after years of use. My old job involved troubleshooting touch-panel faults, and we traced a lot of the failures to early polymer blends that couldn’t stand up to sunlight or sweaty hands. The newer blends, built with diacrylate compounds, actually hold up. So every time a touchscreen manages years under harsh lighting in a store, one can thank this compound for the extra life.

Clean chemistry matters more now than ever. In the past, old-style plasticizers created all kinds of health questions after breakdown products snuck into food or the air. Switching in compounds like 1,10-Decanediol Diacrylate gives manufacturers a shot at creating lower-odor, lower-toxicity products. Major players in the coatings market now focus hard on raw material selection, not just cost, guided in part by stricter rules and customer concerns. LD50 data (lethal dose for 50% of tested animals) for this diacrylate runs higher than for many older additives, so it poses less risk to workers and families.

Plastic waste never really goes away, so manufacturers face growing pressure to reduce reliance on compounds that linger in landfills. Smart use of diacrylate-based materials in applications like wind turbine blades or medical implants extends service life and cuts replacement cycles. The fewer times you have to rip out and redo floors or equipment, the less material ends up in the trash. There’s still plenty of room for improvement, of course—biodegradable versions and better recycling methods need more investment.

As materials science keeps moving, people in the field look for compounds that boost performance without sacrificing safety. 1,10-Decanediol Diacrylate plays a key, supporting role—one that can’t be replaced by just any off-the-shelf plasticizer. Those who’ve worked in product development or maintenance appreciate a chemical that does what it says on the tin, holds up year after year, and keeps both users and the environment a little bit safer.

Anyone who’s spent time in a lab or manufacturing facility knows the line between routine and risky sometimes runs thin. 1,10-Decanediol Diacrylate sounds like a name cooked up in a chemistry textbook, but it’s a staple in coatings, adhesives, and printing industries. It brings flexibility and durability, but also a checklist of health and environmental concerns. From my years working in chemical R&D, I’ve watched even small lapses with acrylates lead to skin irritation, unexpected spills, or in worst cases, costly downtime.

Direct contact can cause redness, itching, or even blistering, especially if you’ve got cuts or sensitive skin. Breathing in vapors triggers headaches or dizziness for some. These compounds don’t just linger on surfaces; they can get into airways if splashed or mishandled during weighing, pouring, or mixing. Eye exposure can leave lasting damage, even after a quick splash.

Working with chemicals like this always brings a bigger-picture worry. Drains and regular trash bins aren’t built for hazardous waste. Careless disposal could let this chemical seep into waterways, taking its strong reactivity along for the ride. Aging pipes and storm runoff turn minor spills in the lab into broader threats.

Before even opening a bottle or drum, personal protective equipment comes out. Nitrile gloves outlast latex and resist breakdown from acrylates. Long sleeves, lab coats, and a decent set of goggles aren’t just for photos. After watching a colleague brush a sleeve against an open flask, double-checking barriers has become second nature for me.

A properly vented fume hood makes a real difference—close enough to contain fumes, but not so cramped that spills become more likely. Keep the area clutter-free. Open chemicals one at a time. Having seen containers leak at seams, I always inspect packaging for cracks or swelling. Fresh air pulls vapors away, and a well-placed exhaust fan can save a headache—literally.

If something spills, absorbent pads and neutralizing agents come out fast. Never use solvents that boost absorption through skin or make the compound react. Pull in a second set of hands if the volume overwhelms. Once, after a hasty solo cleanup, I ended up with irritation that could’ve been avoided by simply calling for backup.

Always label secondary containers, even if it’s just for a quick transfer. I’ve lost count of stories where “mystery jars” cause confusion. Mixing mishaps, even from folks who should know better, often start with something as minor as skipping this step.

Ongoing training sessions pay off. Bring in real-life stories, not just regulatory jargon, to get folks invested. Update standard operating procedures whenever new info about a chemical’s risks comes up—for this compound, changes keep happening as research evolves. Emergency eyewash stations need clear, easy access. Don’t bury spill kits in a corner.

It pays to maintain relationships with waste management vendors. My team learned the hard way that last-minute calls don’t go over well. Pre-arranged pickups keep hazardous waste out of regular bins and dramatically lower stress when audits come through. Store all acrylates tightly sealed and away from sunlight or heat, since even small changes can trigger unwanted reactions.

I’ve always found that communication beats complacency. Every team member should know where the exits are, what to do in a spill, and why the rules exist. Respect for safety isn’t about paranoia; it’s about making sure everyone heads home healthy.

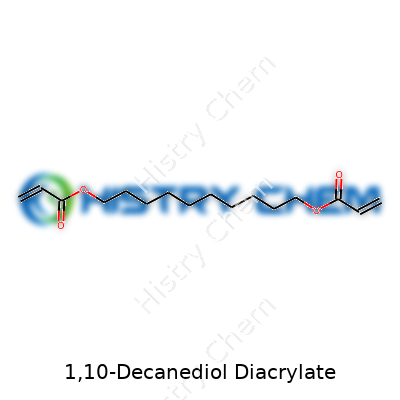

1,10-Decanediol diacrylate comes with a clear, logical design. The molecule has a decane backbone, which means it offers a long hydrocarbon chain, exactly ten carbon atoms holding the structure together. On both ends of this chain, you see an acrylate group linked through an ester bond. Chemists describe this setup as symmetrical: two acrylate groups standing at each end of a straight decane bridge. The structural formula can be illustrated as follows: CH2=CHCOO-(CH2)10-OOCCH=CH2. In simple terms, two reactive acrylate pieces sandwich a decanediol chain.

This composition matters for a few good reasons. The acrylate groups give it the ability to react and crosslink under the right conditions, usually with light or heat. Anyone working in adhesives, coatings, or photopolymer resins finds these reactive points pretty valuable. The length between the acrylate groups controls flexibility and resistance—shorter chains turn out brittle; longer chains give more give. Decanediol forms the sweet spot if you want strength without giving up elasticity.

Heading into manufacturing, I’ve seen why a molecule like 1,10-decanediol diacrylate keeps popping up. Think about polymer composites, 3D printing resins, dental fillings, and UV-cure coatings. Its flexible chain lets manufacturers dial in toughness while keeping products lightweight and durable. In my own experience tinkering in a university lab, swapping shorter diacrylates for this decyl-based structure instantly changed mechanical behavior. Materials toughened up—less cracking, longer wear—especially when stretched or flexed. That performance leap isn’t just luck. The long hydrocarbon middle resists snapping, letting energy distribute instead of concentrating at weak points.

Crosslinking, the reaction triggered during polymerization, comes down to those acrylate ends. They grab photons or heat energy and instantly lock with neighboring chains. In the coatings world, this means finishes that resist scratches, stains, and sunlight better than old-school alternatives. OEMs lean on acrylate chemistry for optical clarity, speedier production, and environmental advantages—cure under lower energy, with fewer volatiles released.

Talking safety—something modern chemistry can’t afford to overlook—I have to mention that acrylate monomers aren’t without risk. Skin and eye irritation pop up in the data sheets, and certain acrylate fumes require ventilation. Lab work taught me that gloves, goggles, and good airflow often matter more than anything written on paper. Disposal also asks care. Acrylate monomers break down slowly, but after polymerization, they settle into inert plastics. Preventing spills and using up leftovers reduces risk to water and soil.

Industry watchdogs and regulators track acrylate monomers, especially around emissions and workplace exposure. Compared to legacy monomers, some acrylate options cut down unwanted byproducts and bring more bio-based alternatives into the mix. As compostable and recyclable acrylate polymers gain traction, even the decanediol core can sometimes come from renewable sources. The push for sustainability asks chemists to revisit classic structures and seek out greener building blocks.

I keep circling back to one lesson. Chemistry, on this scale, shapes every surface we touch—from flooring to electronics. Choosing smart, safer raw materials matters as much as any clever formula. Researchers watch for less toxic acrylate derivatives, safer curing methods, and wider recycling routes. Everybody using acrylate building blocks can look for suppliers invested in greener chemistry. Small changes in the backbone or end group unlock big effect across industries and everyday products.

Anyone working in labs or plants using 1,10-Decanediol Diacrylate quickly learns that not every shelf will do. Safety drives every decision in chemistry, especially with chemicals that can issue nasty surprises if left ignored. This particular compound, popular in advanced materials and certain coatings, brings value but doesn’t take neglect lightly. Over the years, I’ve seen what happens when people treat storage like an afterthought. Air, sunlight, heat—any one of them can turn a simple workday into a mess, and sometimes much worse.

1,10-Decanediol Diacrylate doesn’t like moisture or strong light. Exposure to either one cranks up the risk of polymerization. Picture a container seized with gel, pried open by an unlucky junior tech. Left unchecked, leaking monomers can irritate skin, eyes, or the lungs. American Industrial Hygiene Association studies back this up: acrylates have hurt more than a few hands. Nobody wants that on their conscience or their medical record.

Smart storage starts with containers built for the job. Tightly sealed glass or high-grade plastic keeps the air out and reduces risk. My go-to toolkit always holds proper PPE and spill kits, because even the best system faces bumps or slips. Storage spaces should sit at a consistent, cool temperature—between 2°C and 8°C—far away from heat-producing machines or sunlight streaming through a window.

Fire safety deserves serious respect here. I once visited a startup which kept reactive chemicals above a boiler room. That didn’t end well. Flammable storage cabinets, marked and segregated from acids and caustics, cut down on cross-contamination and the chance of runaway reactions. You want a room nobody rushes through with food or open flames. Modern Material Safety Data Sheets (MSDS) echo this advice: isolation protects both people and the value of the compound itself.

You can’t trust memory, especially in busy workspaces. Every container should scream what’s inside, how old it is, and who last checked it. Quality labeling can seem trivial until a disaster rolls through. Staff need real-world training, not twelve-point font on a dry poster. Quarterly reviews with practical drills help cut accidents. They save money, too—lost stock and accident investigations always cost more than a few hours of training.

Contaminated or expired 1,10-Decanediol Diacrylate creates headaches for everyone. Safely disposing of leftovers with a certified waste handler ends surprises down the line. Every facility should post a clear plan for spills, including eyewash stations and chemical-resistant gloves—don’t ask someone to improvise with paper towels.

People ignore storage rules at their own risk. Making these routines second nature helps teams work faster and with less worry. Every decade brings better research, and listening to frontline staff sharpens protocols. In places where management invests in safe, science-based storage, work doesn’t just get easier—it gets safer for everyone.

1,10-Decanediol Diacrylate finds its home in the world of specialty chemicals. Think of it as a building block in many modern materials. This clear, colorless liquid brings something special to the table, shaped by its unique structure: a decanediol core, capped at both ends with acrylate groups. Its molecular layout gives it flexibility, enabling a good balance between strength and pliability when it sets or cures.

The liquid state stands out right away. At room temperature, 1,10-Decanediol Diacrylate stays fluid, not sticky or syrup-thick like some other resins. Pouring it from a bottle feels much like working with a light mineral oil. Viscosity ranges from 10 to 25 centipoise at 25°C—a number that means very low resistance to flow. This makes blending easy in the lab or at the factory.

It boils at relatively high temperatures, most often above 150°C under reduced pressure. Such a boiling point translates to decent thermal stability under everyday handling. It won’t evaporate much at room temperature, so spills don’t turn into fumes right away. The flash point lands around 120°C, which means careful storage beats unnecessary risk. Flammable, but not quick to catch fire—just respect the safety data sheets.

Density comes in close to 1 gram per cubic centimeter, nearly matching water. Anyone mixing it with powders or pigments can estimate quantities without constant math. Less dense than heavy oils, but not so light that it floats above everything else.

One challenge in many labs and workshops: will a chemical eat through my gloves or countertop? With 1,10-Decanediol Diacrylate, I’ve seen it mix well with most organic solvents—think acetone, ethanol, and standard acrylate-forming partners. Water, on the other hand, leaves it alone. The molecule shrugs off moisture. If tiny amounts of water sneak in, it tends to cloud, but that’s about the extent of the trouble. Solubility in water stays extremely low.

Odor doesn’t muscle its way into the workspace. You catch only a faint chemical smell, comforting compared with the sharper fumes of other acrylates. Working close to it for hours never left me dizzy, provided the area stayed ventilated.

Physical traits shape what chemists and manufacturers can do with materials like this. Low viscosity means it fills molds quickly. It soaks into glass fibers or wood with zero fuss. Polymer cures stay clear, not yellowing or clouding during short UV curing cycles. In my own experience with DIY composites, the result feels smooth—no lumps, no sticky patches.

Stability and low volatility offer added safety during storage and transit. If you’ve watched barrels arrive at a facility, you know the fear of mystery leaks. Here, spills don’t turn into big inhalation risks overnight.

Some of the best outcomes come from learning how this diacrylate holds up to repeated heating, or UV exposures, especially if you’re sealing electronics or optical devices. Labs keep records on degradation under stress and track if residual monomer triggers skin irritation. Safety should always ride up front. Wearing gloves, keeping clean air in the room, and reading updated material safety data sheets make a big difference.

All in all, 1,10-Decanediol Diacrylate stays in demand for its combination of low viscosity, useful boiling and flash points, and easy handling. As research pushes technology along, understanding these basic physical properties becomes more than a box-checking exercise—it lays the groundwork for real, reliable results in every project.

| Names | |

| Preferred IUPAC name | Decane-1,10-diyl di(prop-2-enoate) |

| Other names |

Decamethylene diacrylate

Decyl diacrylate Diacrylate decanediol 1,10-Diacryloyldecane 1,10-Decamethylenediol diacrylate |

| Pronunciation | /ˈwʌn ˌdɛkəˈniːdiˌɒl daɪˈækri.əleɪt/ |

| Identifiers | |

| CAS Number | 4074-88-8 |

| Beilstein Reference | 873278 |

| ChEBI | CHEBI:87134 |

| ChEMBL | CHEMBL1964817 |

| ChemSpider | 5283659 |

| DrugBank | DB14183 |

| ECHA InfoCard | 07e4ce4f-f38a-4a06-9ee2-1361a839c205 |

| EC Number | 401-280-0 |

| Gmelin Reference | 388156 |

| KEGG | C19275 |

| MeSH | C08G61 |

| PubChem CID | 53887204 |

| RTECS number | UA4375000 |

| UNII | 9WKY7R27UE |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C16H26O4 |

| Molar mass | 342.48 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Faint Characteristic |

| Density | 0.973 g/cm³ |

| Solubility in water | Insoluble in water |

| log P | 2.7 |

| Vapor pressure | <1 mmHg (25°C)> |

| Acidity (pKa) | 13.01 |

| Basicity (pKb) | 14.94 |

| Magnetic susceptibility (χ) | -67.5e-6 cm³/mol |

| Refractive index (nD) | 1.462 |

| Viscosity | 59 mPa·s (25°C) |

| Dipole moment | 1.35 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 776.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -711.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6314 kJ/mol |

| Pharmacology | |

| ATC code | |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause an allergic skin reaction. Harmful to aquatic life with long lasting effects. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H317, H319, H411 |

| Precautionary statements | P261, P264, P272, P273, P280, P302+P352, P305+P351+P338, P333+P313, P337+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 1,2,1 |

| Flash point | > 124°C |

| Autoignition temperature | > 265°C |

| Lethal dose or concentration | LD₅₀ (Oral, Rat): >5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >5000 mg/kg (rat, oral) |

| NIOSH | QV5950000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/m³ |

| Related compounds | |

| Related compounds |

1,6-Hexanediol diacrylate

1,4-Butanediol diacrylate 1,12-Dodecanediol diacrylate Neopentyl glycol diacrylate Trimethylolpropane triacrylate |